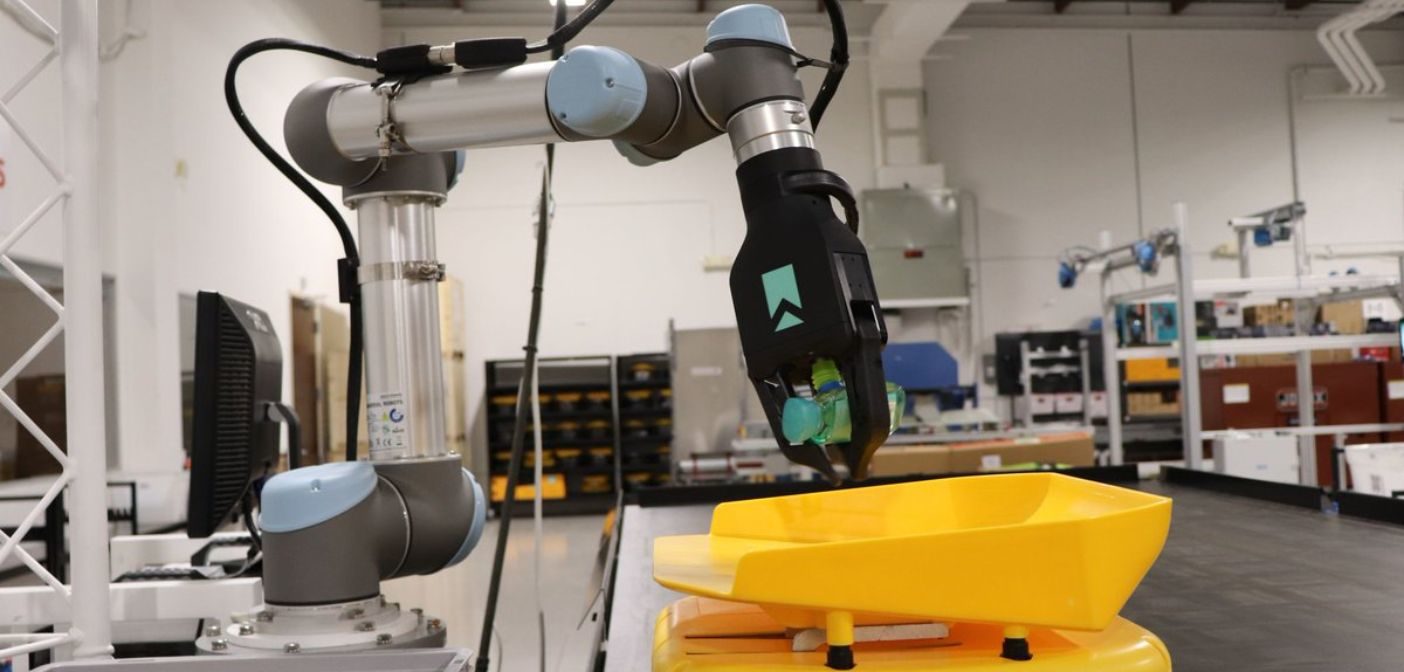

RightHand Robotics, a provider of data-driven autonomous picking solutions for order fulfilment, has launched the RightPick 3 item-handling robot system, the company’s newest generation of its RightPick product suite.

According to Righthand Robotics, RightPick 3 is the world’s first autonomous piece-picking solution designed from the ground up to be integrator-friendly with a modular, industrialised hardware design, well-defined software APIs and international compliance.

RightPick 3 has been designed to pick faster and handle a broader range of items than before, with features such as dense packing and damage-free item handling.

The system is powered by RightPick AI software designed to continuously understand, plan, execute, and learn.

It is supported by fleet management software that provides performance dashboards and item management tools to enable warehouse site teams to optimise throughput.

Yaro Tenzer, co-founder and CEO at RightHand Robotics, said: “The RightPick 3 system achieves an unprecedented level of autonomy with flexibility to be integrated into a wide range of warehouse tasks reliably, despite the inherent variability of picking processes.

“This is a significant milestone for integrators as they can offer their customers a robust automation solution with simple plug-and-play on the path towards lights-out order fulfilment at scale.”

Specific system features and capabilities include: the RightPick processor module, a dual GPU industrial computing platform that processes data more than six-times faster, and is designed for use at elevated warehouse temperatures; a new safety controls unit for easy integration of common warehouse safety components; an integrated kiosk with the RightPick console, a simple user interface; and an updated fleet management system, featuring the Rightpick Control Center for real-time, remote visibility and control.

The overall solution is backed by RightCare service and support, with programmes designed for end-customers and integrator partners to ensure 24/7 operations.