Mining company Vale has deployed four-legged inspection robot ANYmal at its Brazilian mine to help reduce human exposure to hazardous conditions.

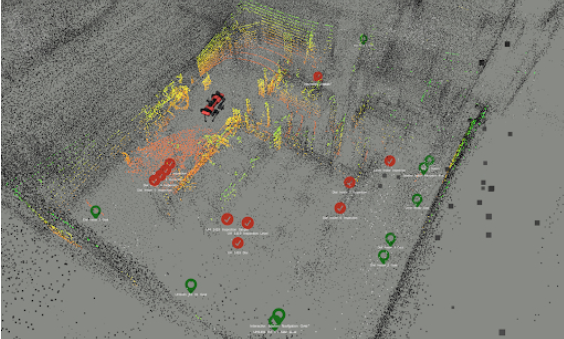

ANYmal, from Swiss robotics company ANYbotics, creates a 3D environment map of Vale’s Cauê Mine and processing facility, and builds a database of its inspection tasks. Once commissioned, the Vale team sends ANYmal out into the facility to perform its inspection rounds autonomously.

The autonomous mobile robot’s first mission takes place on Cauê’s ground floor and contains inspection points such as belts, levers, electrical panels, and water drainage areas. ANYmal collects thermal images and audio samples analysing the temperature and proper functionality of multiple machine belts and high-resolution photos of LED panels to read critical asset data.

During its second mission on the ground floor, ANYmal inspects numerous gauges, dials and levers within one of the facility’s machine rooms in order to measure and ensure proper oil levels.

In the facility’s upper level, ANYmal’s tasks include photographic analysis of the operational state of liquid suction and drainage, electronic panels attached to mill equipment, lubrication gauges, pipe conditions, and thermal temperature analysis of Cauê’s large milling machinery.

With customisable components such as thermal cameras, ANYmal is able to provide Vale with reliable readings throughout the facility, regardless of environmental conditions. For inspection of small objects at high ranges, its high-definition zoom camera and its LED spotlight mounted on the inspection unit guarantees high-quality data collection in reduced lighting conditions.

Rayner Teixeira, digital maintenance coordinator at Vale, said: “Our ANYmal can verify several asset conditions in addition to a circuit of critical spaces, stairs, and complex equipment—all autonomously, and always with the aim of integrating people, technologies and processes that prioritise safety.”

The company added its partnership with ANYbotics highlights it commitment to becoming one of the safest and most reliable mining companies in the world. ANYmal has integrated seamlessly into its team to perform routine inspections and deliver improved reporting during operations and periods of downtime.

Furthermore, by using ANYmal Vale has increased the availability of key team members to prioritise higher-level tasks.

The partnership now aims to integrate robotics below the surface, where conditions are darker, damper, and potentially more hazardous to the human workforce. Vale’s underground mines will be the next area explored by ANYmal.