Japanese company Renatus Robotics, which develops automated warehouse solutions, has launched what it describes as the ‘world’s first’ automated robot warehouse system that leverages its ‘one-stop pick and pack’ technology.

The company claims that its solution enables a single worker to perform picking, consolidating and packing operations all in a single stop. These are operations that have typically demanded workers and dedicated material handling equipment to be involved at every step.

According to Renatus, its system revolutionises inventory management and order fulfilment across many logistics operations, and is especially useful for e-commerce.

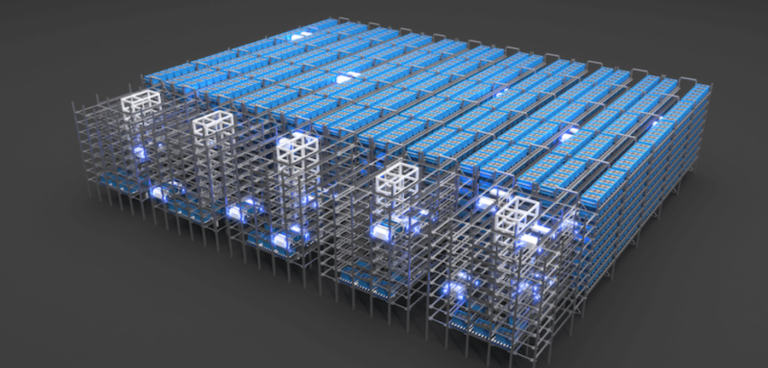

The automated solution uses a 3D storage rack system, equipped with Renatus Shuttles and high-speed lifts, and is managed and controlled by the company’s proprietary software and algorithm package, named Renatus Cortex.

Some of the advantages of the system that the firm highlights include picking efficiency and high storage efficiency, with Renatus reportedly unlocking picking speeds up to 500 lines per hour per worker.

What’s more, automated warehouse systems traditionally require the use of buffering and sequencing equipment in addition to conveyor systems to consolidate all the goods in an order for packing, leading to high equipment and labour costs in many cases.

As a response to this, the Renatus solution was designed to enable goods arrive to workers completely sequenced and consolidated without additional equipment. This is made possible, its developer claims, through the fleet control and its combined software and algorithm offering.

Moreover, the use of dedicated transport methods within the solution, used for the horizontal and vertical transport of goods, reportedly supports speeds of up to 4m/s.

Communications within the system are managed over local 5G for what Renatus calls a stable, high-speed performance. This software and hardware combination supports Renatus’ system to store one million bins and ship more than 300,000 lines per day, the company has said.