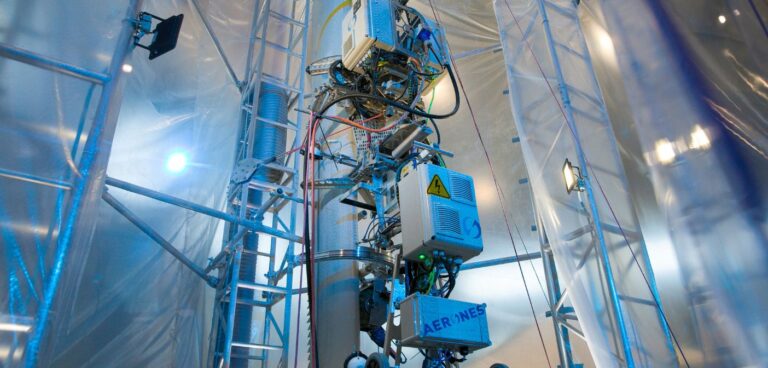

Aerones, a robot-enabled wind turbine maintenance and inspection service provider, has demonstrated a robot that offers a full-service inspection, maintenance and repair of an edge wind turbine blade for ‘the first time’.

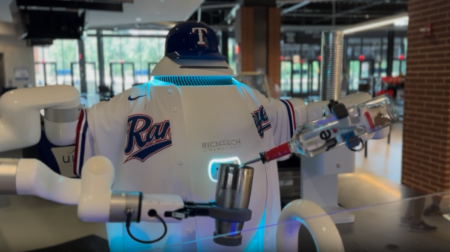

The robot can reportedly perform maintenance five times faster than a human and leverages various attachments to perform different tasks, including refinishing blades with Relest coatings from AkzoNobel.

According to Aerones, the robot can perform maintenance and repair for Level 1-3 Leading Edge Erosion (LEE), meaning it can proactively address erosion.

This, the company claims, makes it a cost-effective solution to stalling progression to Level 4-5 erosion on wind turbines and that it prevents costly repairs further down the line.

The robot was unveiled for the first time in Riga, Latvia today [January 24 2023] at the world’s first factory demonstration of the solution.

“Global energy demand in the next 20-30 years will double, and the steepest growth will be in the near future,” said Danis Kuze, co-founder of Aerones.

“To support the industry’s growth, our goal is to offer a robotised system that can repair wind turbine blades at any moment when it’s necessary.

“We continue to work towards making the robot as resilient as possible to various external conditions, which is why we’ve tested our system in extreme heat, humidity and wind.

“Our ultimate goal is to create a product where wind turbines would only have to be stopped for a short time, or not at all, in order to be repaired.”

What’s more, by making use of a robotic system, Aerones says it is able to eliminate the need for rope access technicians, which is a ‘potentially hazardous’ profession with a 0.64 per 1,000 injury rate.

The robot is also designed to work in conditions of wind up to 15km/s, while technicians are able to work in conditions of up to nine kilometres per second. This means the device can improve the safety of maintenance technicians, perform repairs faster, reduce downtime, all while cutting operational costs.