An automated high-storage-density system for order picking has been installed at the Askul Value Center in Kansai, Japan.

The staged implementation, which will include more than 318 robots from autonomous mobile robot specialist Geek+, is more than 70% complete.

This marks the largest installation of the Geek+ Shelf-to-Person PopPick System in Japan. The staged implementation, which will include more than 318 Geek+ robots, is reportedly more than 70% complete.

Since 2019, Askul has been using the Geek+ Shelf-to-Person Standard System across multiple distribution centres to streamline warehouse operations and boost efficiency.

When Askul expanded its product line, the company needed to grow into a new warehouse automation solution.

According to the robotics company, Askul chose the Geek+ PopPick solution for its high efficiency, high storage density and cost savings. The solution was brought into the site to improve Askul’s customers’ experiences through the provision of a more efficient and effective logistics system.

Hirokazu Kat, president and CEO of Geek+ Japan, said:“The Geek+ PopPick System is designed for high efficiency and can significantly improve the overall productivity of warehouse operations.

“This implementation will showcase to the market the next generation of warehouse automation, setting a new industry benchmark.”

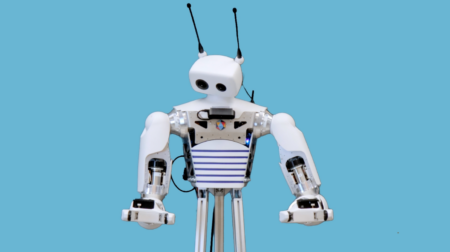

The PopPick System consists of picking robots that transport movable shelves from storage locations to PopPick workstations, where intelligent robotic arms present totes or boxes to the operator.

The system can increase picking speed by up to 500 lines per hour, improve warehouse storage density by 50%, and double throughput capacity, Geek+ has said.