Turnkey solutions company SDI will integrate its materials handling systems and technology with Kindred’s AI pick-and-place robotic solutions following a new partnership agreement.

The collaboration aims to help customers meet increasing retail fulfilment demands throughout the entire year, including peak seasons.

SDI’s distribution centre management system (DCMS) software application incorporates all parts of distribution centre’s operations and can be used for complex waving and management solutions for retail, wholesale, fulfilment and e-commerce industries.

“We are really excited about this partnership,” Krish Nathan, SDI CEO, said. “As an integrator, we’re eager to be able to offer such a great product to our clients and to partner with an innovative company such as Kindred.”

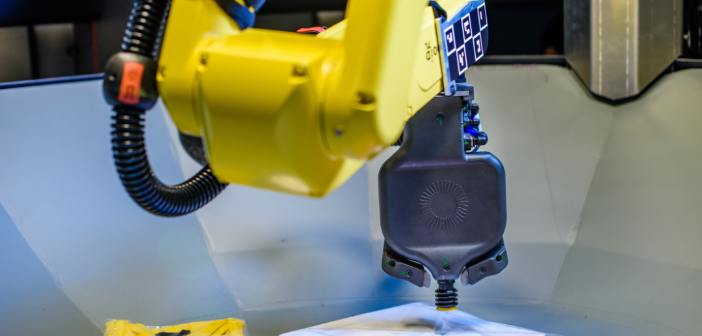

Warehouse associates work collaboratively with Kindred’s Sort robot to sort items into individual customer orders quickly and accurately.

The robots arrive ready to operate, with minimal associate training, and adapt to each distribution centre’s requirements. According to Kindred, its machine-learning algorithms also improve robot performance over time for the entire fleet.

Sort robots utilise the company’s AI-powered Core/AutoGrasp platform, which combines AI-powered machine vision, grasping and manipulation algorithms, to enable them to identify a range of merchandise, including deformable items such as polybagged items, to pick, place and sort into complete end-customer orders.

Additionally, Kindred said it uses AI research and human-in-the-loop data methodology to continuously improve robot capabilities so that picking becomes smarter, faster and more accurate over time.

Kindred Sort robots have picked more than 100 million units in production to date.