Toyota Research Institute (TRI) has been investigating how the application of artificial intelligence (AI) methods can help discover and develop next generation materials to help reduce global carbon emissions.

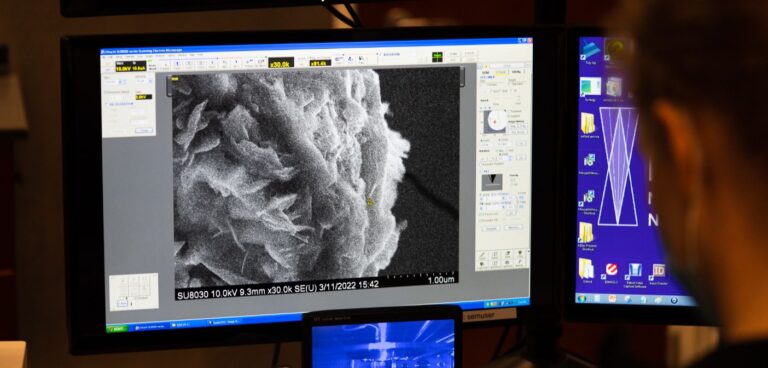

The research centre has been working in collaboration with the Northwestern University in Illinois, USA, to establish the world’s first nanomaterial ‘data factory’ and have developed a machine learning algorithm capable of synthesising materials at ‘record speeds’.

The use of AI methodology differs from traditional trial-and-error research by exploring vast parameter sets, collecting data, then leveraging AI to examine the material’s genome to find the most suitable material for a given application.

The two organisations hope to use this technology to develop materials to drive a global transition towards clean energy sources.

TRI and Northwestern believe this methodology will be applicable across a wide range of applications in the future, including clean hydrogen production, the removal of CO2 from the atmosphere and the development of high-efficiency solar cells.

“Meeting the growing demand for mobility without emitting carbon is a major challenge,” said Brian Storey, senior director of energy and materials, TRI.

“Through this partnership with Northwestern, we have significantly reduced the time it takes to test and find new materials that can be used in batteries and fuel cells to decarbonise transportation.”

Chad Mirkin, director of the International Institute for Nanotechnology and the George B. Rathmann professor of chemistry at Northwestern, said: “This ground-breaking research marks an inflection point in how we discover and develop critical materials.

“Together with TRI, we’re poised to empower the scientific community to find the best materials that power the clean energy transition.”

The algorithm used to sift through Northwestern’s new ‘megalibraries’, a reference collection that reportedly contains more new inorganic materials than have ever been collected and categorised.