CME, a British manufacturer of process automation and packaging machinery, has developed a fully automated solution for pneumatic valve assembly that places a six-axis robot at the heart of the system.

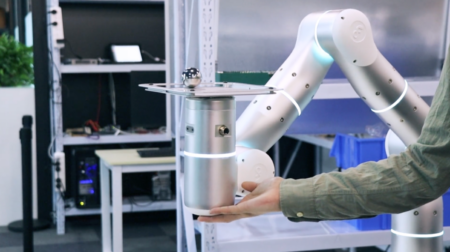

The robot performs a range of pick-and-place, orientation, transfer and assembly operations, with CME claiming it can automatically assemble 600 parts in an eight-hour shift.

The application requires the assembly of a pneumatic valve body, which is made up of several components, including the body itself, a coil, circlip, a label and adhesive, all of which are collected by the robot.

According to CME, this is traditionally a manual process, with an operator requiring 90 seconds to complete the needed tasks.

By transitioning to an automated assembly process, CME said it hopes to eliminate repetitive manual tasks, reduce assembly times and increase both productivity and savings on manufacturing.

Furthermore, the automation of assembly operations enables the introduction of further quality checks to improve quality and yield.

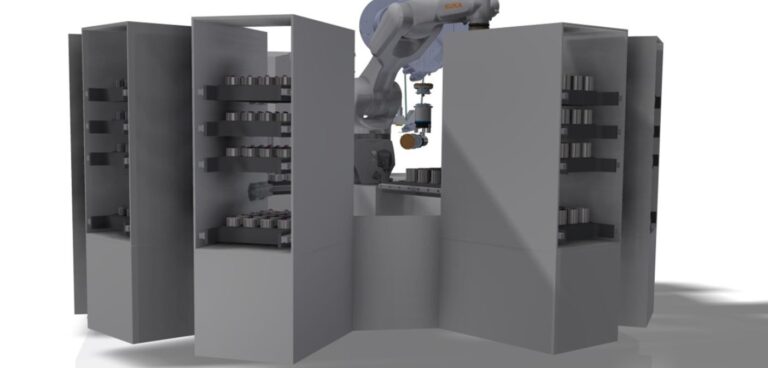

Six cabinets, each holding 100 components, can be found at the rear of the robotic cell. Three of these are fitted with trays containing valve bodies, with the other three holding coils.

As part of the assembly process, the robot is designed to open and close the drawer magazine systems to move parts.

The cell capacity is reportedly 300 assemblies before the device needs to be re-primed with fresh components.

According to CME, total processing time without stoppages (until components run out) is four hours, with an average cycle time of 48 seconds.

The company claims that this marks a more than 45% saving on the initial 90-second cycle time.

What’s more, CME claims that the system is capable of re-tooling, which can reproduce other variant parts.