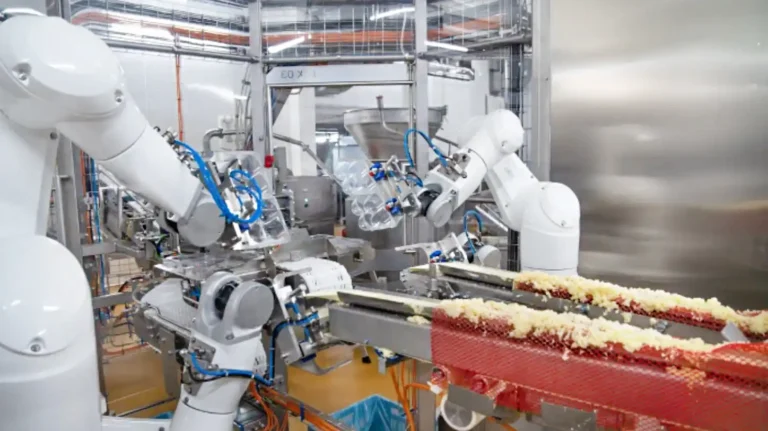

Food production automation developer KRÖNING-Automation developed a potato dumpling packing process which has been implemented by Stäubli’s Stericlean robots.

The packaging process happens at Friweika’s Saxony, Germany facility, where four hygiene robots pack up to 160 potato dumplings a minute, without touching them.

Founded in 1970, Friweika produces a wide range of potato products, including up to 180,000 dumplings daily. As the demand for convenience foods has grown, the company sought to increase output in its dumpling production line.

The new system uses robots to fill blister packs with dumplings without making direct contact with the food. This method helps avoid contamination and preserves product quality.

The robots are specially designed to meet the highest hygiene standards, with features such as resistance to hydrogen peroxide cleaning and the use of food-grade lubricants.

The upgraded line ensures consistent product quality, high productivity, and adherence to strict hygiene protocols.

Marcus Kröning, owner of KRÖNING explained how the robots are able to process the dumplings without touching them: “A robot picks up the blister pack and holds it at an angle at the end of the conveyor belt so that the individual dumplings fall directly into the cavities.

“Depending on the type of blister pack, the robot adjusts its position four or 10 times before the package is filled. The next step is to close the blister pack and transport it to the secondary packaging area.”

Join more than 11,000 industry leaders at Robotics and Automation Exhibition on 25-26 March 2025, at the NEC Birmingham to explore cutting-edge technologies, connect with peers and discover the latest innovations shaping the future of manufacturing, engineering and logistics. Register for free now to secure your place at this premier event!

Join more than 11,000 industry leaders at Robotics and Automation Exhibition on 25-26 March 2025, at the NEC Birmingham to explore cutting-edge technologies, connect with peers and discover the latest innovations shaping the future of manufacturing, engineering and logistics. Register for free now to secure your place at this premier event!