Robotic end-of-arm tooling (EoAT) manufacturer OnRobot has unveiled a new vision system that it says enables all leading robot arms to pick items not presented in the same orientation, shape or size.

The system, called Eyes, offers 2.5D vision, which is said to add depth perception and parts recognition for robot arms via one-picture calibration and intuitive programming.

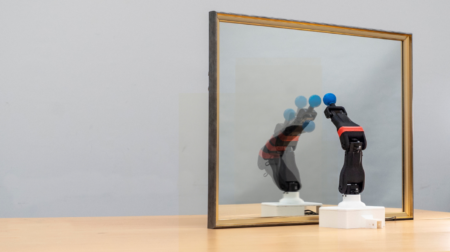

It can be mounted both on the robot wrist or externally, making it suitable for a range of unstructured applications in need of vision guidance.

Eyes reportedly provides consistent positioning with “none of the added complexity of existing vision systems” – such as fixtures, bowl feeders and other hardware – which result in “rigid applications that lack the ability to easily pick different objects or achieve quick changeover times”.

“A significant part of our customer base does not want to be tied to a fixed incoming position of a product they want to pick,” said Enrico Krog Iversen, CEO of OnRobot.

“They would love to eliminate complicated, bulky and expensive part feeders and fixtures to achieve this, but until now such vision systems have felt out-of-reach.

“Our new Eyes vision system changes all that.”

According to OnRobot, unlike other vision systems on the market, Eyes only needs to take a single image for calibration and part recognition, and has automatic focus to work at different distances within the same application.

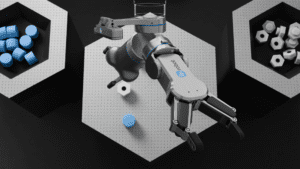

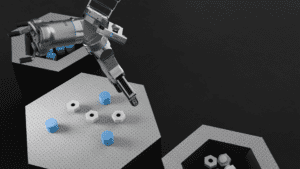

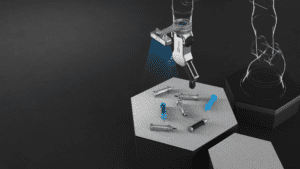

As such, Eyes is said to be suitable for sorting a wide variety of objects or for CNC machine tending with metal parts that are defined by outer shapes, as well as other pick-and-place applications where orientation is important.

Eyes also offers depth perception within its 2.5D vision, which, compared to 2D, adds length, width and height information for the specific part.

“This is ideal when objects may vary in height or if objects must be stacked,” added Iversen.

Furthermore, Eyes integrates with all leading collaborative and light industrial robot arms through the company’s One System Solution, a unified mechanical and communications interface based on its own Quick Changer product.

The new vision system also directly interfaces with other OnRobot devices such as the company’s grippers.

With a dual setup, using a dual Quick Changer, the gripper’s tool centre point can be automatically configured by Eyes, eliminating potential conflicts between different software packages from different tool vendors.

While the optimal mounting depends on the application, according to OnRobot, advantages of having Eyes mounted externally include not having to worry about cables running alongside the robot and the ability to optimise cycle time, as Eyes can take the picture and process this, while the robot is performing another operation.

Want to read more stories like this?

OnRobot launches Soft Gripper for pick and place applications

OnRobot launches new three-finger e-gripper

OnRobot launches new single-pad gripper

OnRobot launches new electric vacuum gripper

Veo Robotics launches vision system for human-robot interaction