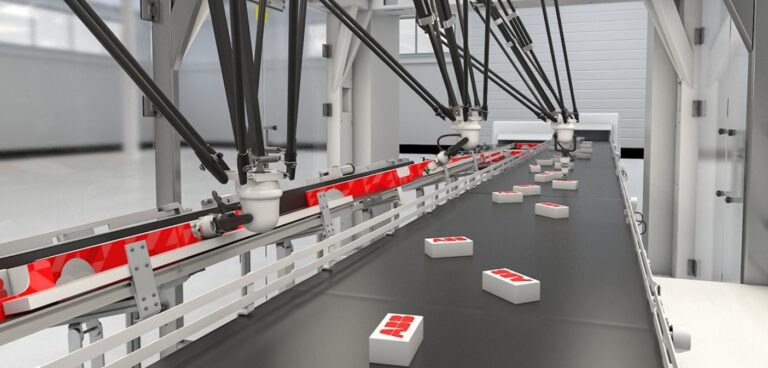

Global robotics firm ABB is expanding its FlexPicker Delta robot portfolio with a new picking robot, the IRB 365.

With five axes and a reported 1.5kg (3.3lbs) payload, ABB claims the IRB 365 is both flexible and the ‘fastest in its class’ for reorienting lightweight packaged objects.

According to ABB, the IRB 365 has been developed in response to a rise in e-commerce. It was designed to suit a range of industries, including food and beverage, pharmaceuticals and consumer goods and can support production speed and adaptability.

The IRB was developed to support applications such as top-loading, secondary packaging, bottle handling, unscrambling, 3D picking, feeding and parcel sorting.

Powered by the OmniCoreTM C30 controller – which ABB claims is the smallest Delta robot controller on the market – the system is built to offer motion control, built-in digital connectivity and more than 1,000 additional software and hardware features.

ABB suggests that, through use of its PickMaster Twin software, the IRB 365 can be integrated into assembly lines within hours. Its digital twin technology also reportedly cuts changeover times from hours to minutes.

The robotics firm also says the IRB 365 can be paired with other robots like the IRB 390 to pick, handle and pack payloads up to 15kg (33lbs).