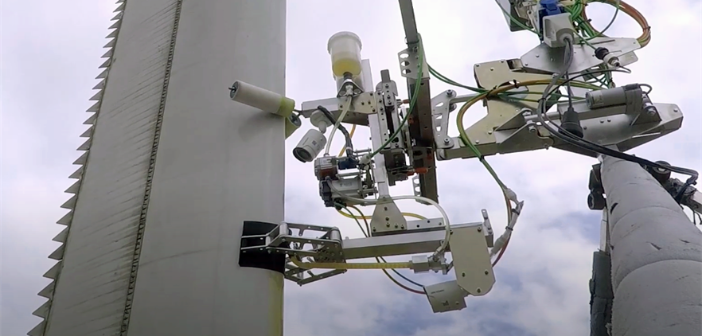

An offshore blade maintenance robot has won an innovation competition launched by GE Renewable Energy and will be tested on an offshore demonstration turbine.

Drone solutions firm Aerones and solar energy company Tethys developed the new offshore transportation and delivery system for onshore wind robotics technology to work offshore.

The robot, which can provide advanced remote inspection, maintenance and repair tasks on offshore wind turbine blades, is scalable and designed to be safer and up to five times faster than conventional rope access, thereby reducing turbine downtime.

Janis Putrams, Aerones CEO, said: “Not only are blades getting longer, conditions are getting harsher, distances to site are increasing and the supply of experienced blade technicians is getting squeezed.

“We provide a scalable robotics solution that offers a full suite of blade services to solve this problem and remain convinced this is the only way for the industry to go to continue to reduce the levelised cost of energy.”

Competition organisers GE, ORE Catapult and KTN said they were looking for a robotics solution to automatically maintain offshore wind turbine blades and reduce unplanned offshore activity during the operations and maintenance phase.

GE said it is committed to offering technical support and guidance on how to deploy the technology on offshore projects.

Vincent Schellings, chief technology officer for offshore wind, GE, said: “Innovative robotics solutions such as this have the ability to significantly reduce operation and maintenance cost for offshore wind turbines like the Haliade-X, the most powerful turbine in operation today.”

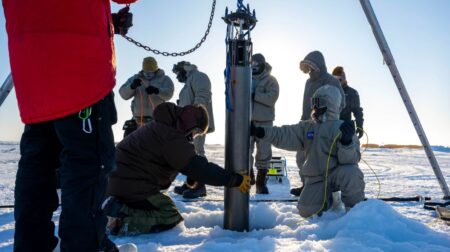

Tethys and Aerones will showcase the system on ORE Catapult’s 7MW Levenmouth demonstration turbine, formerly Samsung’s Fife demo.