Robot-as-a-Service (RaaS) is expected to revolutionise the way oil and gas (O&G) companies approach robotics, according to GlobalData.

The data and analytics company found that industry leaders such as BP, Equinor, ExxonMobil, and Shell are increasingly testing autonomous robots in facilities, with these systems often supported by other technology such as AI.

According to GlobalData, the costs can be off putting and technology companies, such as Fugro, that offer RaaS allow O&G firms to avoid the cost of inventory and obtain robotic services when required.

Ravindra Puranik, oil and gas Analyst at GlobalData, said: “A number of technology vendors are trying to adopt RaaS in addition to selling robotics equipment. This market has considerable potential for growth within O&G as it can save players the considerable costs associated with purchasing robotics systems.”

Furthermore, its thematic report, Robotics in Oil & Gas (2021), discovered that the industry is already actively collaborating with robotics hardware and software technology vendors to implement RaaS.

Filipe Oliveira, thematic analyst at GlobalData, added: “RaaS is possible because of developments within cloud computing in the last decade. Cloud technology has changed the way we work, how we access entertainment, and is now changing robotics.

“Cloud-connected robots are smarter — learning from each other’s experience, instead of just their own — and can be monitored, managed and maintained remotely. Within the O&G industry, tech specialists such as Fugro, currently have an incumbency edge due to their industry know-how.”

The report highlighted a growing list of functionalities tailored to O&G, with robots operating as terrestrial crawlers, quadrupeds, aerial drones, autonomous underwater vehicles, and remotely operated vehicles. Other digital technologies such as AI, cloud computing, and the Internet of Things are also improving the performance of robots for O&G applications.

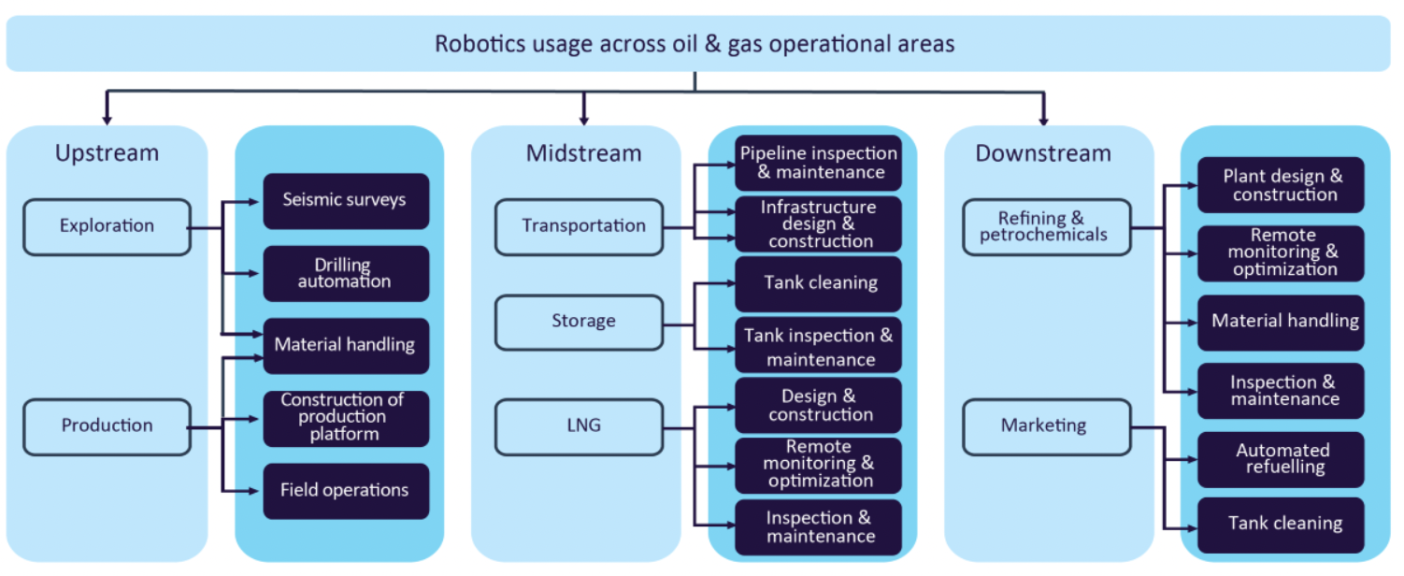

Puranik continues: “Robotics will have applications throughout all workstreams within O&G. For upstream operations, uses include automated drilling or conducting seismic surveys; for midstream, they can be used for inspection and maintenance, as well as for design, construction and remote monitoring; while downstream applications include automated refuelling and material handling.

“Robotics offer high reliability and efficiency, while also improving overall operational safety. Various terrestrial, airborne and submerged robots are already playing critical roles in several high-stake O&G projects across the value chain.

“AI is expected to develop further, enhanced with computer vision — the ability of computers to derive meaningful data from images — and context-aware computing capabilities.”