Malaysian energy company Petronas has announced that it is testing an autonomous inspection robot at one of its offshore oil and gas platforms.

Developed by ANYbotics, ANYmal C operates on four legs and has been designed to navigate challenging terrains safely.

Petronas relies on robotics to enable unmanned industrial inspections in its production operations.

The company’s long-term partnership with ANYbotics focuses on bringing robotic routine inspection to both offshore and onshore facilities.

Exposed to extreme weather conditions, the Petronas offshore oil and gas facility was deemed a suitable test location for ANYmal due to the site’s demanding environment, which includes steep industrial stairs.

Iskandar A Mahmood, manager for robotics at Petronas, said “Our plants are built for humans and often provide only little space for general passages.

“We have been testing ANYmal in various challenging situations and are impressed by its versatile mobility that doesn’t require us to make any adaptations to our facility.”

ANYmal features IP67 water and dust ingress protection to provide required long-term reliability.

“Minimising the maintenance needs of the equipment is important to reduce overheads,” added Mahmood. “The industrial-grade design of ANYmal is key in these harsh environments exposed to salty air,”

Petronas field-tested ANYmal C first on its onshore training platform to evaluate the robot’s inspection capabilities.

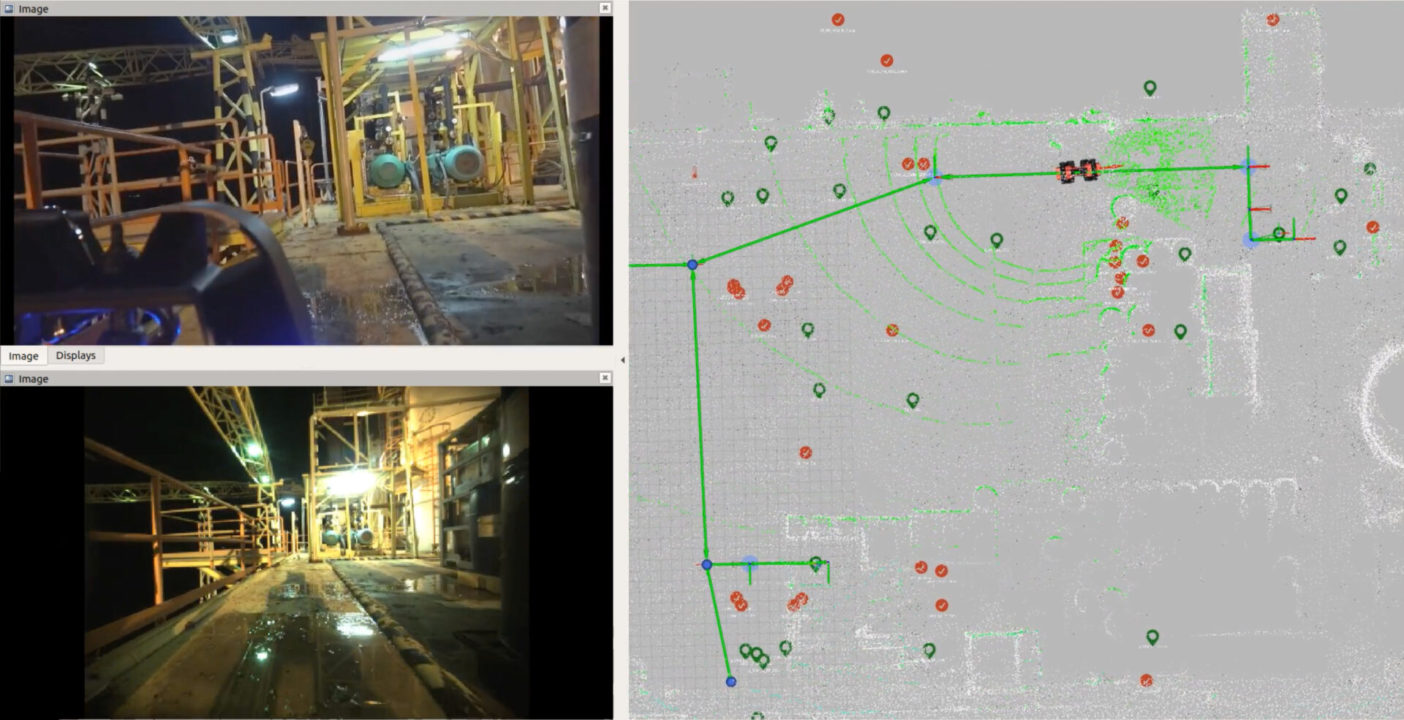

Tasks included general visual inspection, digital readouts of analogue and digital gauges, thermography, and acoustic analysis of rotating equipment.

Following successful onshore functional tests, Petronas’ robotics team then performed a multi-week deployment on Petronas’ offshore platform Dulang B.

“The offshore tests validated ANYmal’s performance under adverse conditions including slippery terrain, strong winds, and operations in day and night,” said Mahmood.

“Offshore platforms have large open spaces toward the ocean that are challenging for autonomous navigation.

“However, the lidar-based localisation of ANYmal has proven robust even in these cases, and we were able to successfully test all functionalities, including autonomous charging on a docking station.”

Petronas and ANYbotics are currently co-developing a specialised version of ANYmal for potentially explosive environments. It is planned to be ready for commercial use by 2022.

The ex-certified version of ANYmal is being designed according to the IECEx international standard and is intended for deployment in Zone 1 areas.

Fauzy Omar Basheer Othman, head of Petronas’ facilities of future, said: “Our motivation is to deploy robotic solutions to reduce HSE risks and OPEX by minimising offshore workforce deployment and logistics.

“We intend to use ANYmal to improve our workflows with better data tagging and automatic reporting.”