Fuzzy Logic, a developer of command-and-control solutions for industrial robots, has partnered with and machine vision company Visionic to develop a robotic Non-Destructive Testing (NDT) system for French nuclear reactor business Framatome.

This software and hardware package is designed to be used by non-roboticist NDT operators, which the partnership said separates it from existing solutions on the robotics and NDT markets.

According to the collaboration, for NDT technologies to be deployed efficiently there needs to be a controlled, laboratory-like environment, which is difficult to achieve in field conditions. Framatome has to deal with this same challenge when inspecting components in the primary circuits of nuclear power plants.

To overcome these challenges, Framatome looked to use industrial robots in an innovative way, leading to Fuzzy Logic and Visionic developing the Platform for Robotic Inspection and Maintenance for Unstructured Settings (PRIMUS) platform.

PRIMUS software and hardware platform is designed to allow NDT service providers to respond to infrastructure inspection requests quickly and efficiently.

The first step is to model the environment as it is at the time of the inspection. Any additional elements that could potentially hinder the trajectory are then integrated into this modelling step.

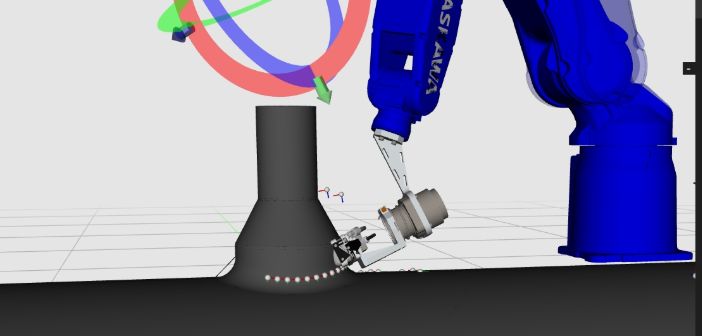

In the second step, a robot is placed next to the welded areas of the pipes. The inspection probe must be moved with precision, this requires the use of a robot to achieve accurate positioning and orientation.

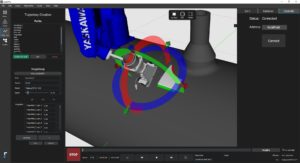

Using software developed by Fuzzy Logic, operators can set up the robot quickly. The 3D sensors integrated on the robot allow the robot to be easily realigned to its real environment.

Trajectories can be determined in seconds with a few mouse clicks, Fuzzy Logic said. The combination of the complex trajectory calculated by the Fuzzy Studio and the 3D scan of the weld structure by Visionic generates the inspection path adapted to the real surface.

The final step consists in the inspection of the weld by ultrasound. This method has never been used for NDT before, and the partnership said its results are more accurate thanks to the control of the probe positioning, with prior adjustment based on a 3D scan of the surface.

Visionic supplies the robots and optical system. Fuzzy Logic provides the programming environment, allowing programming to be done by non-roboticists and eliminating many of the setup steps.

Ryan Lober, CEO and co-founder of Fuzzy Logic, said: “Framatome, like many other industrial corporations, are pushing the limits of what we think we can do with industrial robots. However, expert-level tools are a limiting factor.

“By offering a solution that is accessible to non-experts, we are paving the way for using robots in these applications, which were once thought impossible. ”

Framatome added the PRIMUS system has enable inspection time to be reduced from two weeks to one day.

Read more about the use of robotics by the nuclear industry in the January 2022 issue of Robotics and Automation…