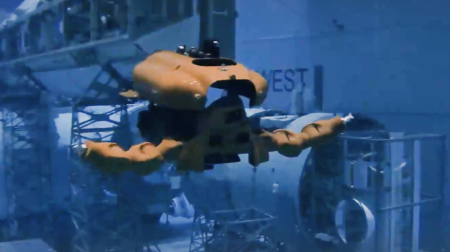

A consortium of UK companies have introduced the Friction Stir Welding Robotic Crawler (FSWBot), a world-first solution for the internal repair and restoration of pipelines.

Supported by Innovate UK, the FSWBot project seeks to integrate several state-of-the-art technologies including friction stir welding, milling, patch deployment and ultrasonic NDT, onto a robotic system, which can be deployed to conduct repairs on pipelines without the need for the pipeline to be closed down for the duration of the restoration.

The project is being led by Cumbria-based Forth Engineering and includes The Welding Institute, Joining 4.0 Innovation Centre, Innvotek and London South Bank University.

According to Forth Engineering the project has been attracting attention from around the world after being showcased at the British Manufacturing and Fabrication in the Offshore Energy Industry event in Aberdeen in November.

Peter Routledge, project manager, Forth Engineering, said: “Interest is really building, including from Saudi Arabia, the USA, Canada, France and Spain.”

Friction stir welding is a solid-state welding process that generates enough frictional heat to soften or plasticise the metal without melting it, allowing metal components to be forged together at the joint line.

This system will determine if a patch weld can be made in steel pipe under oil, and that a representative FSW system can be made small enough to operate in a 36-inch diameter export pipe.

Mark Telford, managing director of Forth Engineering, said: “As a company we have developed a worldwide reputation for developing a range of robotic solutions for use in harsh environments.

“The tools we have developed over the years have been for, and used by, Sellafield, to successfully solve challenges in the nuclear industry. So, our technology is tried and tested in harsh environments.

“There’s a fantastic opportunity for other businesses and organisations in the UK and across the world, whether that’s other nuclear operations, or oil and gas, renewables, and perhaps areas we haven’t even thought of, to make use of that technology, and to share their challenges so we can develop the FSWBot in ways to help them.”

The technology will feature in a presentation at a Transformative Robotics for Industries day at the fourth annual Institute of Electrical and Electronics Engineers UK and Ireland Robotics and Automation Society Chapter Conference, held at the University of Manchester on January 22.

A presentation will also take place at a conference in Amsterdam in February and at the Friction Stir Welding International Symposium in Japan in May.