Okuma America Corporation (Okuma), a producer of CNC machine tools and automation systems, has announced the launch of a new line of automated robotics, the Okuma Robot Loader (ORL) series.

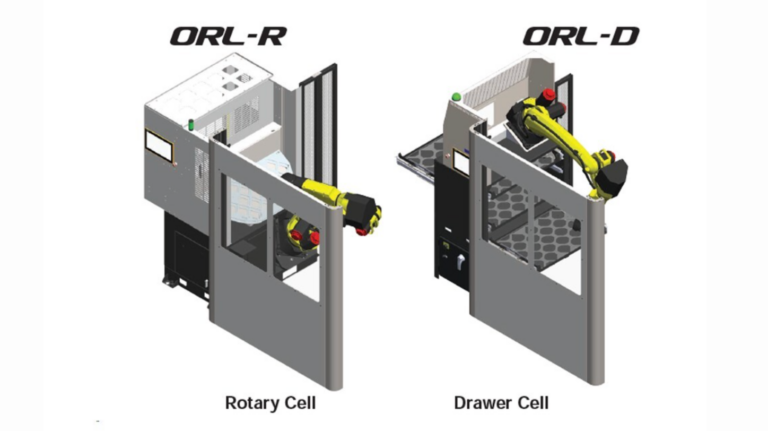

The ORL series includes three innovative products designed to enhance productivity and efficiency by automating the loading and unloading of workpieces.

The ORL-D, also known as the Drawer model, can reportedly hold up to 92 workpieces, with an expandable option for 180 smaller workpieces.

Okuma has said the ORL-R, or rotary model, can store up to 166 workpieces, while the ORL-MC, the machining centre model, can support up to 288 workpieces with its patented MultiGrip workholding. This makes it suitable for diverse manufacturing needs.

All ORL units feature a compact design, requiring just eight to nine feet of floor space, and utilise industry-leading Fanuc industrial robot arms capable of handling up to 25 pounds, the company said in a statement.

Wade Anderson, Okuma America’s vice president of engineering, commented the ORL series, highlighting its potential to transform machine shop operations with its efficient integration and space-saving design.

He added: “Our team is excited to bring the ORL series to market and showcase its capabilities…With its compact footprint and easy integration process, an ORL unit can quickly make an impact for machine shops of any size.”