Festo Didactic, an equipment provider for industrial and technical education, and Sick, a developer of sensor solutions, announced a new educational program with a focus on robot safety awareness and rich data experience, with the ambition of helping close the manufacturing skills gap.

The program was developed to holistically teach students robot safety and to support students in learning the latest industry best practices.

With safety as the main focus, Festo Didactic and Sick created a Safety Awareness Bundle that combines an educational curriculum with hardware. The content of the curriculum focuses on robot risk assessments, as well as the implementation of the system approach compared to what the pair call “automation à la carte”.

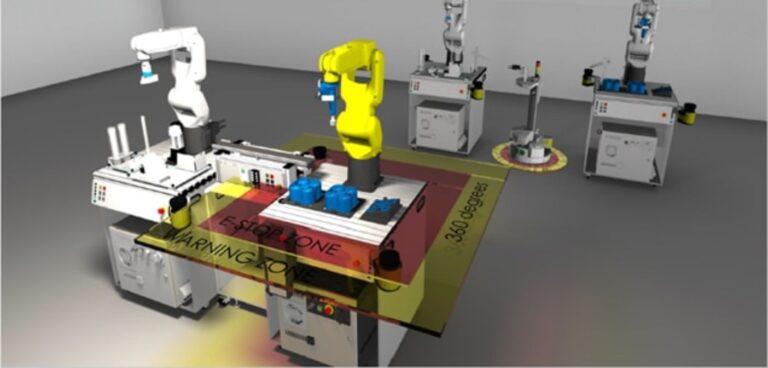

The hardware component of the program consists of a Festo Didactic manufacturing production system (MPS), a simulated Cyber-Physical Smart Factory with six-axis robot, SICK area scanners, safety PLC and safety relay.

“With such a demand for smart manufacturing methods to be demystified, students who have been exposed to this sort of implementation have a real advantage when it comes to applying to jobs compared to students not provided the same experiential learning and job training,” said Ted Rozier, director of Engineering at Festo Didactic North America.

“This approach ensures that students can qualify for jobs locally.

“Regardless of the robot manufacturer, Festo and Sick have created this content to be agnostic, which means it will align to the best practice of any robot manufacturer, allowing students to become adaptable contributors from day one on the job.”

The curriculum was designed to enable students to understand both the importance of risk assessment and what to do once digital data has been captured. It guides them through a six-step process of ensuring robotics and automation equipment safety, which includes an understanding of: risk assessment; safe design; technical protective measures; administrative measures/ information about residual risks; machine validation; and deployment of machinery.

Students who use the program are also set to learn the definitions of key terminology, such as performance measures, areas of severity, frequency and avoidance.

In the past, robotics education has traditionally focused on a specific robot brand and only the robot operation itself. By adding safety curriculum to Festo’s product line MPS (Manufacturing Production System) and Cyber-Physical training equipment, the two companies claim that students can now develop a well-rounded working knowledge of how robots are tightly integrated as a system in the real world.

Although the safety awareness bundle has been established in several community colleges and universities across the US, its use is not limited to current students. Workers may also sign up for the safety awareness course to upskill their knowledge base in robotics.