Researchers from MIT’s Computer Science and Artificial Intelligence Laboratory (CSAIL) have developed a system that uses a pair of soft robotic grippers with high-resolution tactile sensors to successfully manipulate freely moving cables.

Until now, standard approaches have used a series of slow and incremental deformations, as well as mechanical fixtures, to manipulate thin flexible objects such as ropes, wires, or cables. However, as the shape of such objects constantly changes, the robot constantly senses and adjusts the cable’s position and motion.

The CSAIL system, which features no added mechanical constraints, could be used for both industrial and household tasks, to one day enable robots to help people with things such as tying knots, wire shaping, or even surgical suturing.

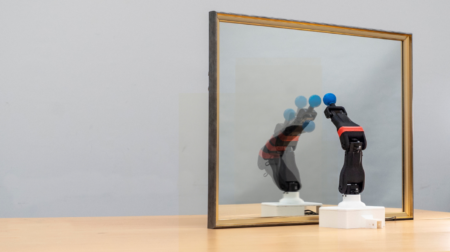

The team’s two-fingered gripper system features lightweight and quick moving opposing fingers that allow nimble, real-time adjustments of force and position. On the tips of the fingers are vision-based GelSight sensors, built from soft rubber with embedded cameras. The gripper is mounted on a robot arm, which can move as part of the control system.

A perception-and-control framework enables cable manipulation. For perception, the GelSight sensors are used to estimate the pose of the cable between the fingers and to measure the frictional forces as the cable slides. Two controllers run in parallel: one modulates grip strength, while the other adjusts the gripper pose to keep the cable within the gripper.

When mounted on the arm, the gripper could reliably follow a USB cable starting from a random grasp position. Then, in combination with a second gripper, the robot can move the cable “hand over hand”, as a human would, in order to find the end of the cable. It could also adapt to cables of different materials and thicknesses.

The robot also performed an action that humans routinely do when plugging earbuds into a cell phone. Starting with a free-floating earbud cable, the robot was able to slide the cable between its fingers, stop when it felt the plug touch its fingers, adjust the plug’s pose, and finally insert the plug into the jack.

However, the team observed that it was difficult to pull the cable back when it reached the edge of the finger, because of the convex surface of the GelSight sensor. Therefore, they hope to improve the finger-sensor shape to enhance the overall performance.

In the future, the team said it plans to study more complex cable manipulation tasks such as cable routing and cable inserting through obstacles, as well as eventually explore autonomous cable manipulation tasks in the automotive industry.