Sick has launched an ultra-compact all-in-one 2D vision sensor, the InspectorP611, which can be mounted on robotic arms to conduct inline machine vision inspections.

According to the manufacturer, with the InspectorP611 2D vision sensor and pre-installed Quality Inspection SensorApp users can configure inline inspection, part localisation and measurement tasks to run automatically on the device.

Small enough to be mounted where it is needed inside a machine, the InspectorP611 is designed for measuring or verifying the finer details of small assemblies, electronics components or glue beads.

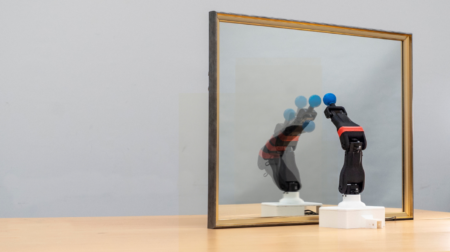

Furthermore, as it is lightweight it can also be mounted on robot arms to provide real-time quality checks and positioning for tasks such as the insertion of small screws.

Users can also connect the system to a web-browser interface to configure a choice of machine vision tools to run directly onboard the camera.

Additional flexibility is also built-in to expand or customise inspections, together with the option to progress to Sick’s Intelligent Inspection Deep Learning SensorApp for more challenging inspections, when required.

“It might be the smallest of the InspectorP600 family of programmable 2D vision sensors, but the SICK InspectorP611 packs the power of its larger siblings into a miniature device that fits in the palm of your hand,” said Neil Sandhu, Sick’s UK product manager for imaging, measurement and ranging.

“Whether you are a novice or an expert, it is quick and easy to configure your machine vision application using the onboard image processing tools provided within the Sick Quality Inspection SensorApp.

“It’s also simple to download additional free tools for specific applications, such as glue bead inspection, while more experienced users have the flexibility via the programming interface to access time-saving, ready-made code so they can fast-track customised inspections. Meanwhile even inexperienced users can progress to Deep Learning, starting from a low cost of ownership.”