Ocado Group has unveiled seven new robotic and automation technologies for its Ocado Smart Platform (OSP) designed to tackle the rise of rapid delivery companies and address labour shortage challenges.

Revealed during a briefing to analysts, Ocado Re:Imagined innovations include a new grocery fulfilment bot; lighter grids; robotic arms that pick groceries directly from the grid; a virtual distribution centre; a capability for short lead time deliveries; and a capability for powering retailers’ storefronts with the same technology behind the OSP.

Tim Steiner, chief executive of Ocado, said the new technology was “one of the most significant steps forward” in the company’s history and a “game changer” that would enable the group’s retail partners to automate picking in smaller local warehouses and provide a “compelling immediacy proposition” that could take on rapid-delivery firms that have grown during the pandemic.

Steiner said that while rapid-delivery firms fulfilled a role “for distressed purchases”, they offered customers “a very limited range of products and the most expensive last-mile delivery costs”.

According to Steiner, the new technologies are “transformational in the market and really drive our innovation forward” in a way that would “shatter the existing rules of the industry”. He said: “All companies we are working with are having challenges employing enough people to work”, so new technology would mean that workers could be redeployed from certain jobs to others and he did not expect waves of redundancies.

The new robots are intended to be combined with new software systems that will enable local delivery vans to be loaded more quickly, mixing orders made less than an hour before they set off with those made the night before. Steiner said the advancements would quicken the roll-out of new warehouses and mean that Ocado’s technology could serve different types of customers, not just supermarket clients.

Software will also link up smaller warehouses to create a system where products delivered to one can be shared between several locations to help improve efficiency.

Referencing the cause of the fires at Ocado’s Erith and Andover warehouses, Steiner said that improvements in its new robots meant there was less risk of the machines damaging their batteries. “The advancements to these robots are not focused on fire retardancy but they will slightly reduce the risk rather than increase the risk,” he said.

For Ocado Group, Steiner said Ocado Re:Imagined should offer higher returns from lower capital costs and operating expenses, a greater total addressable market available to the business, and the expectation of an acceleration in the sign-up of new partnerships, in addition to further orders from existing OSP partners.

Founded in 2000 by three former Goldman Sachs bankers, Ocado currently has seven warehouses in the UK that fulfil online grocery orders for Morrisons and its own brand, which it owns in partnership with Marks & Spencer. The online grocery retailer also licenses its software and automated warehouse technology to overseas supermarkets, including Kroger in the USA.

Ocado Re:Imagined – Introducing seven key innovations

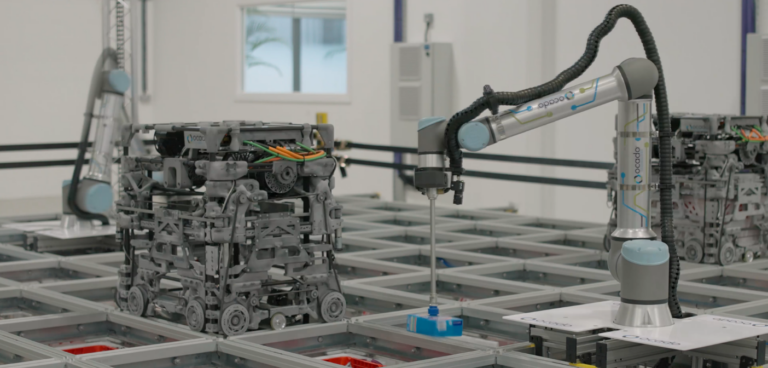

- The 600 Series bot: Picks groceries from the grids in Ocado’s warehouses. With more than half of its parts are 3D printed, the 600 Series Bot is 80% lighter than its predecessor, making it cheaper to build and operate, as well as ultra-energy efficient.

- The 600 grid and optimised site design: The lightweight design of the 600 Series bot will enable Ocado to build lighter grids – the section of the site where groceries are picked – in weeks, rather than months, and at a lower cost. As 600 Series bots require less power to achieve the same throughput from the same footprint, new sites will require less chill equipment, lowering energy consumption levels and overall construction costs.

- Automated Frameload: This process automates the loading of totes with ready-for-delivery customer orders onto delivery frames ready for dispatch, replacing the manual process currently in place. According to Ocado, automation of this process will reduce labour costs by 40% and eliminate the most physically demanding jobs.

- On-grid Robotic Pick: A robotic arm with machine vision, deep reinforcement learning and advanced sensing capabilities that enables it to pick tens of thousands of products of varying shapes, sizes, weights, and fragility and pack them densely in bags with human precision and accuracy. Expected to be introduced in new and some existing warehouses from the end of this year, the robtoic arm could reduce the need for workers to pick and pack groceries into shoppers’ bags by up to half initially, and 80% longer term.

- Ocado Orbit: Designed to remove the need for a physical distribution hub, “the world’s first virtual distribution centre” splits the full range of products offered by a retailer across a number of small fulfilment centres located closer to the customer. It is powered by AI and machine learning, creating a supply ecosystem shared by the multiple smaller footprint warehouses.

- Ocado Swift Router: Enables delivery of last-minute, short-lead time orders to be picked, packed and delivered alongside larger, longer lead-time orders on the same grid and via the same van. This means OSP partners can offer both immediacy and longer-lead time services, while customers get choice, value and lead times that work for them.

- Ocado Flex: Partners can use their own pre-existing webshop and app solutions while taking advantage of the intelligence of OSP and keeping their existing touch points with their customers.