A new software update has been released to enable users to intuitively programme complex paths for industrial robots.

In robotics programming, complex paths refer to complicated or intricate movements or routes that a robot needs to follow. They are often characterised by non-linear movements (motions that don’t follow a straight-line path) or non-trivial movements (motions that are complex or not straightforward for the robot to understand).

These paths can involve navigating around obstacles, reaching specific locations or performing sophisticated manoeuvres. Depending on the application required of the robot, these paths can vary in complexity.

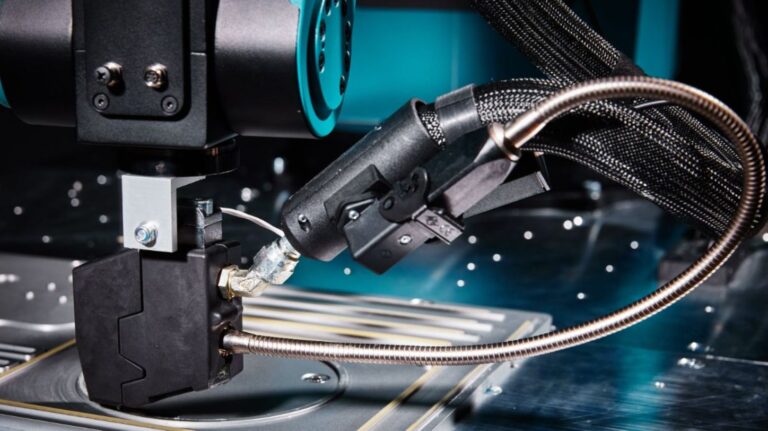

German robotics firm Fruitcore Robotics has unveiled the new update, intended for its line of HORST industrial machines.

It hopes that this will make automation processes more user-friendly for the company’s range of digital robots, as well as improving process reliability to help users better monitor processes.

Read more: Fruitcore Robotics releases industrial robotic arm with payload ‘up to 8kg’

As a result, firms can unlock higher system availability and improved collision avoidance, the company has said. This is because the update is designed to replace the need to laboriously teach a large number of support points to avoid an obstacle, thus saving valuable time in demanding programming environments.

According to the firm, the graphical user interface of the control software also helps reduce set-up time for a range of industrial processes. Previously, the software was limited to textual programming.

The new feature is intended for use in the automation of path-controlled processes, such as those for applications like gluing, varnishing, assembly and joining.

Fruitcore Robotics has said that, by navigating this interface, users can programme any complex path in a few minutes, with these time savings meaning the entire robotic application to be set up within a few hours – even if users have no experience in this area or coding knowledge.

A further function to accompany the update includes storable variables, which help users to make their systems more reliable by saving the status of programmes even when the system is paused.

The latest developments in robotics and automated technologies used in industrial processes will be on show at the Robotics and Automation Exhibition, which will be held on 19-20 March 2024 at the NEC Birmingham. Register now to attend the UK’s biggest exhibition dedicated to robotics and automation.