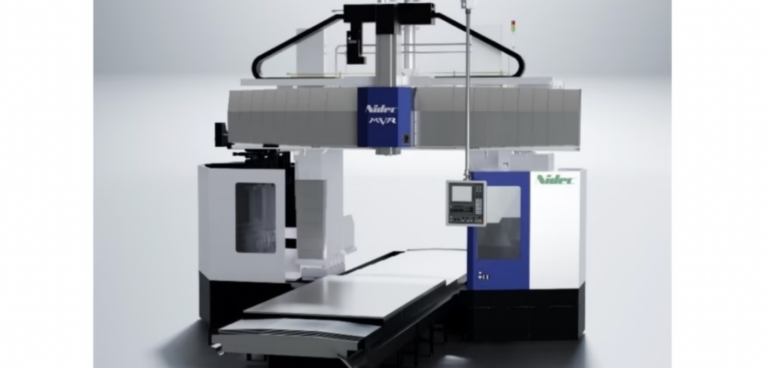

Nidec Machine Tool Corporation announced the launch of MVR-Ax, a series of new models of double-column machining centres.

The new range was developed to offer an easy-to-use solution for manufacturing sites that process large-size components.

Together with its predecessors, the MVR-Ax series can reportedly use a number of options – ranging from a table size that can accommodate large-size workpieces, to an abundance of attachments to the main axis, to automated functions such as a palette changer. This is to support a range of manufacturing applications.

High-performance grinding technology and operability and maintenance tech have been introduced to enhance the MVR-Ax machining centres’ overall productivity.

The machines will be available to users both domestically and overseas to help Nidec branch into new markets.

The machining centres in the MVR-Ax series are equipped with a main axis that rotates 6,000 times per minute to machine large-size workpieces and with a gear drive main axis which works at 4,000rpm, with a maximum torque of 3,430Nm, for deeper cutting operations.

Combined with resilient structures within the main unit, which are designed to remain undamaged from high torque, the products have sturdy ram main axes that enhance the cutting capability during ram protrusion, while enhancing the performance of the machining of tall components’ lateral sides.

Nidec claims that a large number of attachments enable the series to machine objects of various shapes, including narrow sections, multifaceted surfaces, slant planes and adjustable surfaces.

The individual axes’ fast-forwarding speeds are what Nidec calls ‘top-class’ for the sector. The reported speed of the x-axis is 30m/min, 32m/min for the y-axis, 20m/min for the z-axis and for 5m/min for the w-axis. According to Nidec, this shortened non-cutting time makes the MVR-Ax series highly productive.

The MVR-Ax series is installed with NidecNavi, an operational assistance function to help the operator make NC programs and perform centring work efficiently, and the simple collision prevention function to prevent tool-work collision.

The company’s internet of things (IoT) platform, Diascope, has been established to provide support for the MVR-Ax series.

The products’ other features include, among technologies to enhance their environmental performance, an idling stop function for the oil cooler and a hydraulic unit to reduce electricity consumption, as well as other energy-saving properties.

The MVR series was designed to achieve an optimum mechanical performance, as well as improved usability and environmental performance, based on what Nidec claims are user-friendly, secure and supportive designs.

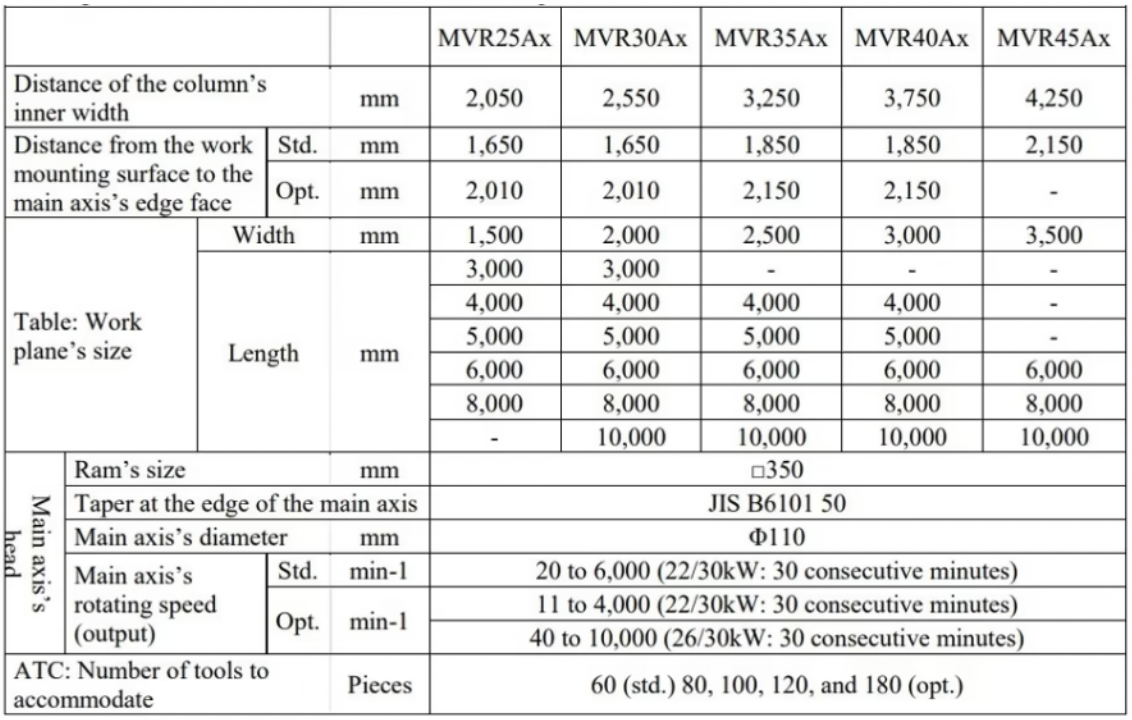

The main specifications of the double-column machining centres in the MVR-Ax series are as follows: