Mitsubishi Electric has announced a new partnership with Hal Robotics to advance both adoption and roll-out of operator-controlled industrial robots capable of variable and complex tasks and applications.

Hal Robotics recently launched ‘decode’ software, which was developed to offer operators and process knowledge specialists a tool to adapt robots without programming expertise.

Barry Weller, product manager – mechatronics, Mitsubishi Electric Automation Systems UK, said: “The importance of Hal Robotics’ ‘decode’ software cannot be underestimated. Allowing operators to more easily integrate their human experience and industry knowledge into key processes and non-uniform manufacturing will be key to improving end-user efficiency, especially given the skills shortage that continue to affect the manufacturing sector.

“We’re looking forward to the future with Hal Robotics and excited to see how its ‘decode’ software will be implemented across multiple sectors.”

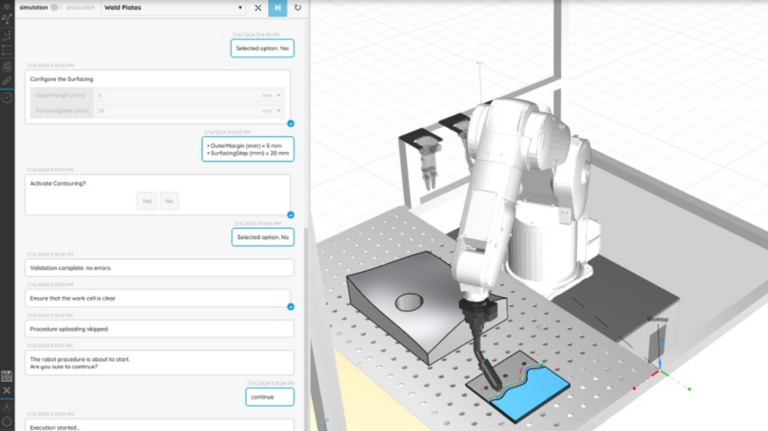

According to the partnership announcement, Hal Robotics’ framework provides systems integrators and robot users the tools needed to establish up complex robotic toolpaths, simulate and validate procedures, as well as automatically send programs to the robots for execution.

As a result, Hal Robotics said, ‘decode’ assists with the removal of hard-to-automate, varied and laborious tasks that previously required constant human input.

What’s more, non-uniform tasks can now be automated without the extensive set-up and training investments typically associated with bespoke solutions.

A key benefit of the partnership is that this software can now be integrated across the Mistubishi Electric’s range of small-scale six-axis Melfa industrial robots.

On the agreement, Sebastian Andraos, CEO and co-founder of Hal Robotics, commented: “Automation has traditionally been associated with repeatable applications.

“By contrast, many manufacturing tasks requiring intricate manipulation of parts and non-uniform results are often viewed as too complex to be carried out by industrial robots. Our ‘decode’ software aims to upend these assumptions.

“By giving operators the opportunity to rapidly influence and change processes to suit the nuances of individual applications, reliance on integrator input can be reduced. Our new partnership with Mitsubishi Electric will allow us to increase access to automation technologies and plug a skills gap often found on factory floors regardless of sector.”