Comau, a provider of industrial automation products and systems, has been unveiled as the first industry partner of Intrinsic, which hopes to develop solutions to make industrial robotics more accessible and usable.

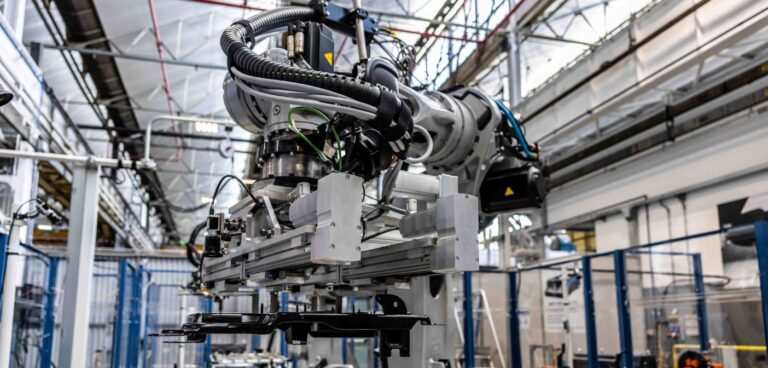

Comau has recently used Intrinsic’s new Flowstate developer product and underlying platform to create a modular solution to enable the assembly of a plug-in hybrid electric vehicle (PHEV) supermodule.

What’s more, Comau wants to use the Intrinsic platform to help customers benefit from capabilities such as object pose estimation, robot automatic path planning with collision avoidance, controlled moves until contact, peg-in-hole applications and force-sensing assemblies.

According to the company, some of the benefits of the platform include implementation and integration of Intrinsic’s software powered by artificial intelligence (AI). Comau has suggested this could help it to develop scalable solutions and pre-configured application templates to quickly deploy new or modified applications.

“We are excited to have partnered with Intrinsic towards our shared vision of democratising robotics,” said Pietro Gorlier, CEO of Comau.

“Looking forward, we will continue to leverage the synergies with Intrinsic and our expertise in collaborative, mobile, wearable, and safe robotic solutions to move closer to achieving software-defined, AI-enabled robotics, which is indispensable for all industries and areas with low automation levels.”

The company is likewise the longest standing innovation partner of Intrinsic, with Comau reportedly contributing both expertise and talent to testing and validation processes.

Wendy Tan White, CEO of Intrinsic, said: “Partnering with Comau over the years has brought our team a tremendous amount of expertise, knowledge, and real world use cases to focus our efforts on.

“The development of Intrinsic Flowstate has been expedited through Comau’s willingness to innovate together on solving hard problems in new ways. We’re excited for what’s next and what it will mean to the solution builders of today and tomorrow.”

The software platform is also designed to drive increased robotics adoption and better cost-effectiveness by helping companies access automation through straightforward deployment. It is equipped with a low-code graphical interface to help make robot programming intuitive-to-use for non-experts.