At this year’s Robotics and Automation exhibition Rollon, Europe’s largest linear rail manufacturer, will be showcasing its newly re-designed Smart and Plus System linear actuators, as well promoting its newly extended range of 7th axis platforms for robot transfer.

During the two-day event, taking place at Coventry’s Building Society Arena on 02-03 November 2021, Rollon will offer their consultation services on linear motion in the automation industry. As specialist manufacturer of linear rails, telescopic rails, linear electric actuators, and actuator systems (including 7th axis). Rollon’s experience and product range is designed to offer a solution for almost every application.

Rollon’s in-house customer technical support for design, sizing and customisation ensures a product fit for purpose. Whether it be high speed, high load, harsh environment, limited space or straight forward 3 axis gantries, Rollon aims to offer high quality, robust and reliable products.

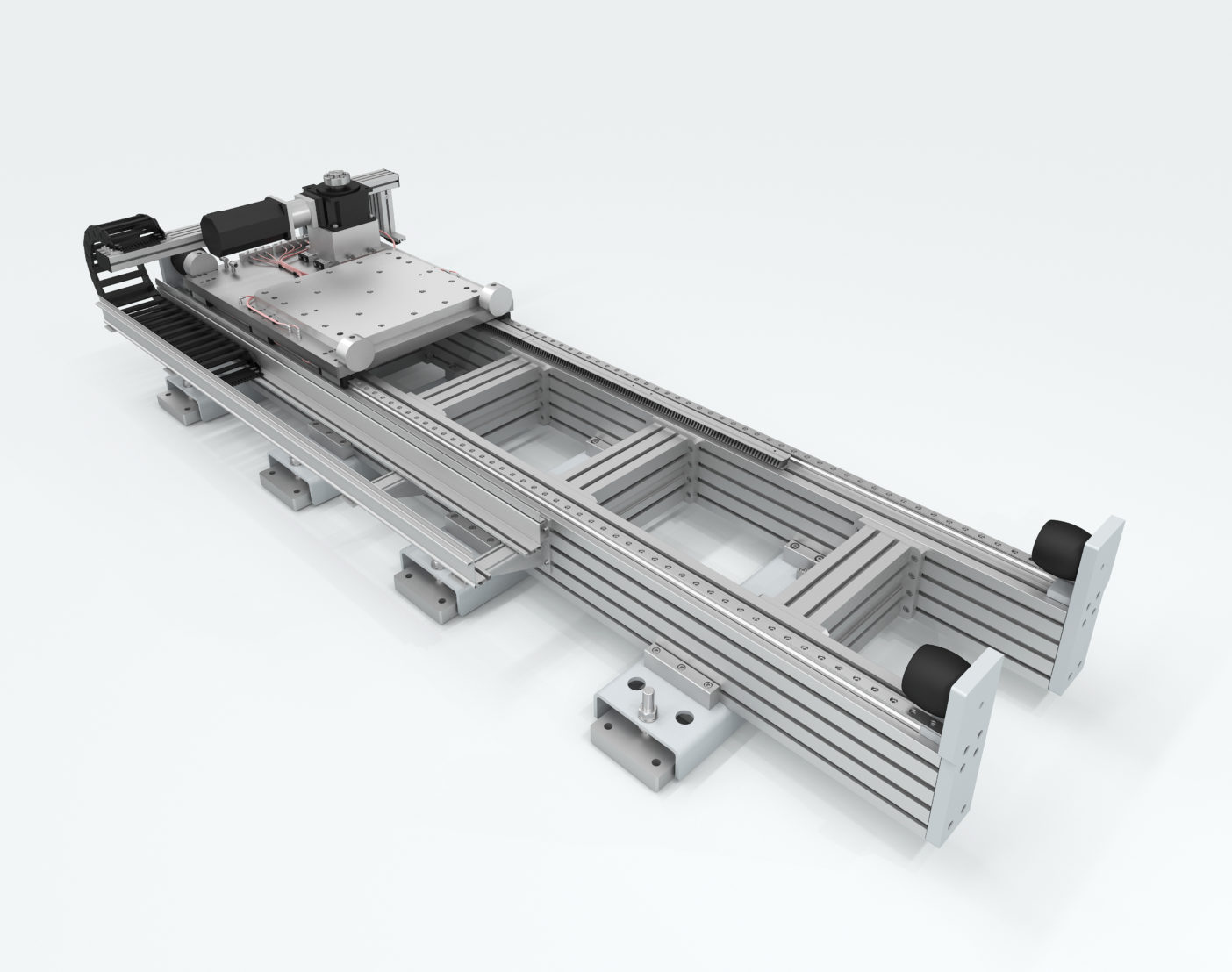

The re-design actuators include the ELM and ROBOT products from the Plus System family and the E-SMART and R-SMART from the Smart System range.

The Plus System family (the protected linear actuators with anodised aluminium profiles, self-sustaining structures and toothed belt transmissions) introduces drive heads with hollow shafts. Thanks to these new features, the gearbox can be mounted on the actuator directly by the client, a considerable improvement in terms of time and cost, and a substantial reduction in time to market, according to Rollon.

Clients can now also remove the cover belt without Rollon’s intervention, thanks to the newly integrated quick release of the block.

The Smart System range, a family of linear actuators closely related with the Plus system, offers an attractive price-quality ratio, with very high performance and a simple and precise construction. Products from the Smart line now have a black transmission belt and new carriages.

The new range of 7th axes, dedicated to the lightweight and collaborative robotics sector, offers five new models: three single-axis and two double-axis. Rollon introduces the belt drive here with zero-backlash pulleys.

The systems offer numerous advantages in terms of silent movement, guaranteed dynamics, and reduced maintenance. In addition, the new axes offer simplification and efficiency, by positioning the motor at the drive head as oppose to onboard the carriage. This reduces the overall weight to be moved along the axis and simplifies cable management.

Rollon (Stand 516) will be at Robotics and Automation 2021 on 02-03 November at the Coventry Building Society Arena.

For more details, go to:

www.roboticsandautomation.co.uk