Northern Regional College and Queen’s University Belfast have been working with collaborative robots (cobots) to innovate welding processes for fabrication businesses.

The Robot Assisted Welding project has introduced cobots as relatively low-cost welding aids to support the assembly of components during welding processes.

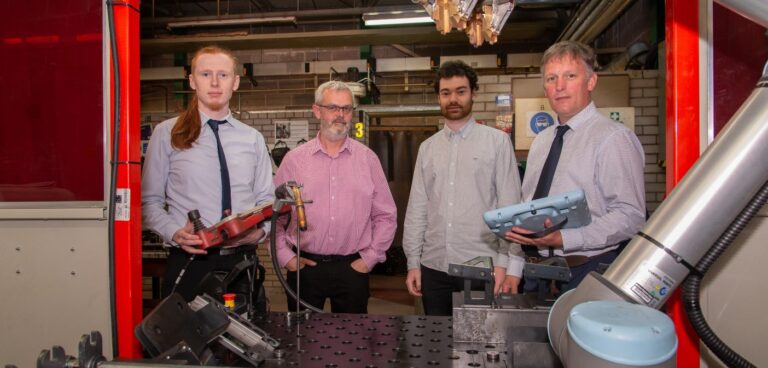

The opportunities of robot-assisted welding were discussed at a showcase hosted by Northern Regional College in Ballymena, Northern Ireland.

Alan Reid, principal lecturer for industry engagement at Northern Regional College, said: “There are two variants of the assisted welding robot.

“The first makes use of a collaborative robot that functions as a part loader and manipulator, while a manual weld operator holds a welding torch in a static position.

“The second makes use of a collaborative robot as a part loader and manipulator, while an automated welding robot carries out welds.

“For both manual and automated welding processes, there is an improved quality of weld, reduction in cycle time, minimum tooling costs and a consistency in technique, all of which can help give businesses in the fabrication sector a competitive advantage.”

Furthermore, a case study of the offline programming and simulation of a cobot assisting an industrial robot was demonstrated to highlight offline programming for a simulation of the physical world and of the control interface between the two robots.

The Robotic Assisting Welding project was funded by the Department for the Economy Connected programme, which is is designed to promote collaboration and knowledge exchange between academia and SMEs.