Researchers from Imperial College London and interdisciplinary Swiss research institute Empa have built a fleet of flying 3D printers, designed to function like bees, for in-flight repairs to buildings and structures.

The research was published in Nature, with the research team suggesting that the drones could be used in hard-to-reach locations for manufacturing or post-disaster reconstruction.

Both on-site and factory-based 3D printing is gaining momentum in the construction industry, with static and mobile robots being used to print materials for construction projects.

Using drones for 3D printing represents a new approach, which co-opts building methods seen in the natural world from creatures like bees and wasps.

The drones in the fleet, known collectively as Aerial Additive Manufacturing (Aerial-AM), work as a team, being fully autonomous while flying but overseen by a human controller, who can intervene if needed. The fleet works from a single blueprint and adapts its technique as the drones work.

Lead author Mirko Kovac, professor at Imperial’s Department of Aeronautics and head of Empa’s Materials and Technology Center of Robotics, said: “We’ve proved that drones can work autonomously and in tandem to construct and repair buildings, at least in the lab.

“Our solution is scalable and could help us to construct and repair building in difficult-to-reach areas in the future.

“Our fleet of drones could help reduce the costs and risks of construction in the future, compared to traditional manual methods.”

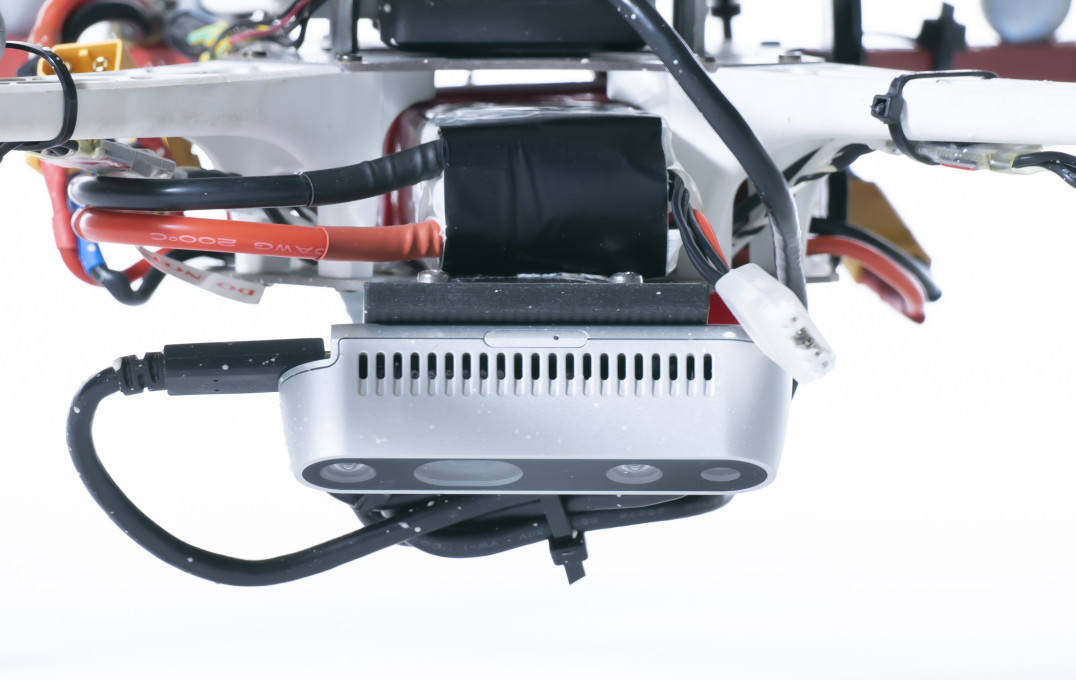

BuilDrones (R) 3D print material during flight and ScanDrones (L) continuously measure the material output for quality control and influence the BuilDrones’ next steps.

Aerial-AM uses both a 3D printing and path-planning framework to support the drones as they adapt to changes or variations in geometry of the structure as construction progresses. Their behaviour can change to ensure they meet build specifications, with manufacturing accuracy of five millimetres.

To trial the drones, the research team designed four bespoke cementitious mixtures for the bots to manufacture with.

The proof-of-concept prints included a 2.05m (6.7ft) high cylinder (made up of 72 layers) with a polyurethane-based foam material and an 18cm (7.1 inches) high cylinder (made up of 28 layers) with a custom-designed structural cementitious material.

The researchers now plan to collaborate with construction companies to help validate the solutions by further demonstrating the drones’ repair and manufacturing capabilities.

The research behind the drones, titled “Aerial Additive Manufacturing with Multiple Autonomous Robots” by Zhang et al., was published on 21 September 2022.

Credit: Video taken at the Imperial College London Aerial Robotics Laboratory by all partners (Imperial College London, University College London, University of Bath).