A self-climbing, autonomous robotic system able to conduct installation work in an elevator shaft has been deployed commercially for the first time across two customers projects in the Asia-Pacific region.

Developed by Schindler, a Swiss elevator and escalator provider, the Schindler Robotic Installation System for Elevators (R.I.S.E) was deployed in Shanghai, China at the end of December 2021 to help install five elevators in Tower 2 of the Xujiahui Center, one of the largest commercial complexes in downtown Shanghai.

In addition, the robot has commenced installation on 10 elevators at Avenue South Residence, a residential project in Singapore and the world’s highest prefabricated pre-finished volumetric construction building.

“Schindler R.I.S.E contributes to greater safety and efficiency on high-rise construction sites,” said Paolo Compagna, Schindler COO. “This innovation enables our clients to complete their projects faster and more efficiently, which has become even more important at a time when many are faced with global construction site delays.”

To date, the installation of elevators has been a manual task, with mechanics entering an elevator shaft to determine the correct mounting position of guide rail brackets, before drilling holes in concrete walls to position anchor bolts that hold the brackets.

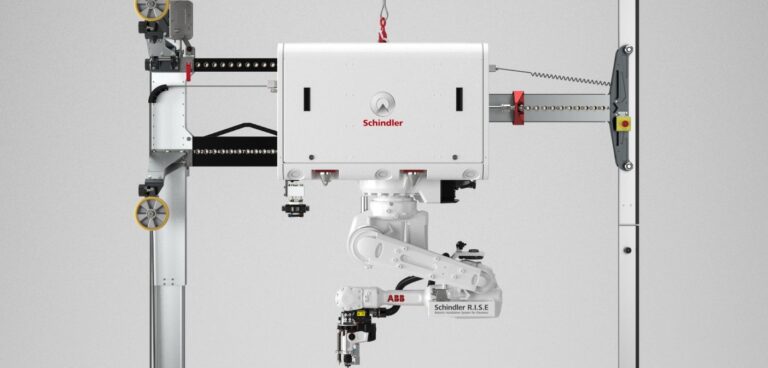

Schindler R.I.S.E has been developed to automate this part of the installation process, making elevator fittings faster and more accurate while also improving health and safety conditions for technicians.

As previously reported by Robotics & Innovation in January 2020, Schindler launched a pilot project to test the R.I.S.E. solution in collaboration with university of science and technology ETH Zurich and ABB Robotics.

The robot selected for the pilot was an ABB IRB 2600, which has a reach of 1.65m and a payload of 29kg, and the solution comprised an autonomous installation system that moves independently from floor to floor by means of an automated hoist.

The installation system uses an algorithm to calculate tolerances and repositions the holes as necessary. Before starting, the robot scans the shaft wall to determine if there is hidden rebar underneath or if the concrete surface is uneven.

Sensors check to ensure the hole has been drilled in the right place before the robot hammers in the anchor bolts and moves on to the next drilling location. Although a camera is mounted on the platform to allow remote viewing and all data related to drilling the hole is documented, the system operates autonomously.