Japanese construction company Obayashi Corporation has started to build a dam almost entirely with robots, reports Nikkei Asian Review.

The site of the trial project is a concrete dam in Mie Prefecture, on the southeast coast of Japan’s main island. The 84m-high structure is slated for completion in March 2023.

Obayashi has developed automated equipment to stack concrete layers to form a dam. To further streamline the process, a plant has been built near the site to mix sand and gravel with cement to make concrete.

Addressing the Japanese construction industry’s labour shortage and ageing workforce – 35% of all workers are now 55 or older, according to the Japan Federation of Construction Contractors – Obayashi’s automated system is expected to be a game-changer in dam construction, as well as in other applications.

“By transferring expert techniques to machines, we’re able to analyse what was once implicit knowledge,” said Akira Naito, head of Obayashi’s dam technology unit.

Every process for constructing the 334m-wide dam will reportedly involve some form of automation. This includes the initial work of establishing the foundation, and pouring concrete to form the body. The dam’s body is built in layers by pouring concrete into 15m2 partitions.

Tower cranes that pour the concrete are controlled remotely by office computers, which also monitor the positioning of the partitions and the progress of construction. Humans will man the cranes for safety reasons, but the machines are self-operating.

While concrete layers that are uneven are usually brushed down by human workers until they are flat, Obayashi has developed machines that handle the brushing, with the frequency of the cyclical brushing and the pressure on the surface both automatically controlled.

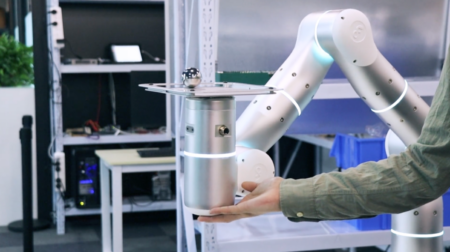

As poured concrete builds up, the forms used to give it structure need to be raised to keep unset concrete from leaking out. Normally, multiple skilled workers in heavy machinery operate in tandem to gradually lift the forms, calling out to each other to coordinate their movements. However, Obayashi has developed a robot to handle this task, allowing for humans to be removed from the process entirely.

Obayashi said its automation solutions have increased productivity by about 10%, and it plans to acquire more know-how so it can eventually reduce the amount of manpower it needs. “Eventually, we may be able to cut building time by 30%,” said Naito.