InOrbit, a developer of cloud-based RobOps (robot operations) solutions, has announced integration with Alfred Kärcher, a provider of cleaning technology, bringing real-time observability, optimisation and newly launched advanced operations capabilities to Kärcher’s autonomous machines.

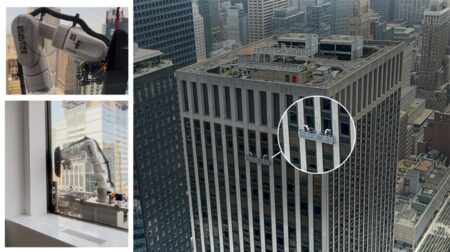

Kärcher is one of the largest developers of industrial cleaning equipment. Its line of Kärcher Intelligent Robotic Applications (KIRA) has been rolled out to 78 countries around the world. InOrbit and Kärcher have worked together to support the KIRA B 50 autonomous floor scrubber, arriving at a joint solution for efficient monitoring of robot health, advanced incident management and the optimisation of mission success.

InOrbit has introduced Advanced Incidents, which leverage multi-parameter programmatic rules to enable the management of common autonomy exceptions and mission execution services. Extending the recently launched Configuration as Code support, a RobOps best practice, InOrbit’s platform is designed to ensure that any issues that may result in degraded performance or service interruption can be identified, logged and in many cases resolved through remote interventions, promptly setting robots back on track.

Kärcher has built its autonomous cleaning solution on top of the InOrbit platform, allowing efficient execution of cleaning missions with limited human intervention, thus freeing up people to carry out other tasks. From getting real-time data about individual robots, to managing the overall fleet efficiency through key performance indicators and ensuring full autonomy through advanced remote support.

Florian Pestoni, InOrbit’s co-founder and CEO, said: “Kärcher has created one of the smartest cleaning robots in the world. InOrbit extends this intelligence to the cloud, augmenting what the robots can do on their own and enabling a complete view of robot operations at scale. InOrbit is helping Kärcher clean up.”