Advanced industrial automation provider Comau has collaborated with machine builder Siscodata for the development of a robotic cell designed to clean and manipulate high-end, pre-printed cosmetic bottles without leaving a single scratch.

With the aim of increasing the production capacity for Cosmint, a premium cosmetic manufacturer who works with some of the world’s biggest names in the industry, the System Integrator used two Comau NJ-40 robots within a high-speed depalletising solution able to pick, rotate and clean custom-printed plastic bottles at an accelerated rate of 150 pieces per minute. The new cell replaces three standard machines that were previously installed at the Cosmint facilities.

Challenged to design a complex solution in only four and a half months from start to finish, Siscodata, with whom both Comau and Cosmint have a long-standing relationship, successfully delivered the jointly engineered system despite the timeframe.

The fully integrated system protects the aesthetic quality and purity of the final product, achieves the desired production rate of .45 seconds per bottle and ensures mechanical, electronic and electrical efficiency. It also enables Cosmint to trust that the end-customer receives a product that is free from contamination and 100% compliant to their rigorous quality standards.

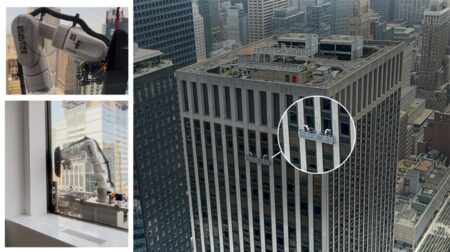

The automated depalletising solution features two Comau NJ-40 6-axis articulated robots that are designed to guarantee the speed, precision and repeatability the application requires. With the help of special grippers and a high-resolution 2D camera, each robot picks a series of bottles from the fragile, honeycombed carton containers used for shipping.

Working in tandem at very fast speeds, the robots rotate the bottles before moving them to a cleaning station to remove over 99% of residual particles or contaminants left over from the production, shipping and depalletising processes. Th partnership added this part of the solution is quite complex and requires synchronised “on the fly” movements by the medium-payload robots to handle a production rate of more than 9,000 bottles an hour.

Francesca Grieco, engineering manager at Cosmint, said: “We are particularly satisfied with the Comau robots, which have allowed us to reach our target of creating a system that is 100% reliable from a performance, quality and electro-mechanical standpoint, and will guarantee the exceptionally high cleanliness standards specified by our end customer.”