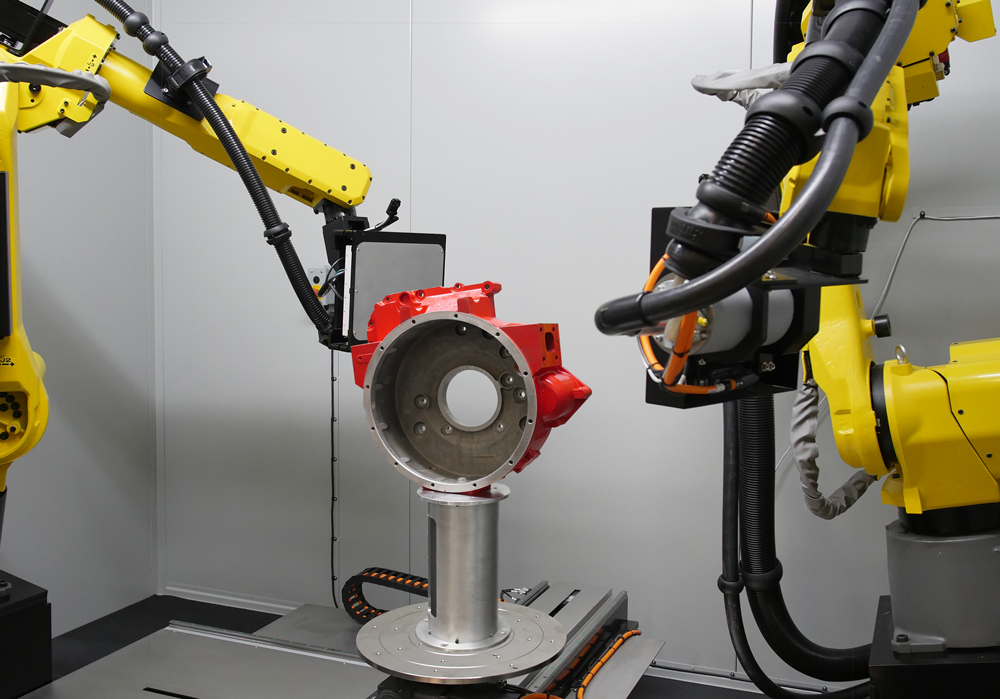

X-ray systems company North Star Imaging (NSI) has introduced its Dual RobotiX precision technology, which features two robot arms working together to scan large parts.

Dual RobotiX’s interface enables operators to x-ray inspect large parts using six-degrees-of-motion at any given point, thereby providing image accuracy, less complex fixturing and faster turnaround times.

Furthermore, the solution’s motion programmes allow an operator to programme the robot and configure the image acquisition parameters through a single software interface, eliminating the need to learn another software programme.

Dual robotiX is an add-on device for NSI’s largest standard system, the X7000. It can be used for R&D, failure analysis, quality control, internal measurements, high-speed 3D scanning, and 3D metrology.

According to NSI, the technology can also be deployed by industries including aerospace, automotive, electronics and medical.

NSI said it offers as-needed inspection services at sites across the UK, USA and China.