ABB has expanded its range of IRB 760 industrial robots for press automation applications in the automotive industry.

The IRB 760PT is a flexible press tending solution that reportedly offers 25% faster cycle times compared to other robot-based press automation solutions.

According to ABB, the revised design reduces interference in the robot’s fourth axis, which eliminates potential interference between the robots and the press.

What’s more, the robot can move freely without colliding with equipment such as press clamps without compromising the overall working area.

Antti Matinlauri, head of product management for ABB Robotics, said: “We’ve reinforced our press automation portfolio with our fastest-ever press tending robot.

“Our new IRB 760PT not only offers optimised speed and die interferences in press tending applications, it is also a flexible and reliable solution that can be implemented quickly and can easily be repurposed to handle changing future requirements.”

The IRB 760PT is capable of handling loads of up to 450kg and features an automatically change tool, which enables the robot to quickly adapt and be reprogrammed to handle new products without the need for re-engineering.

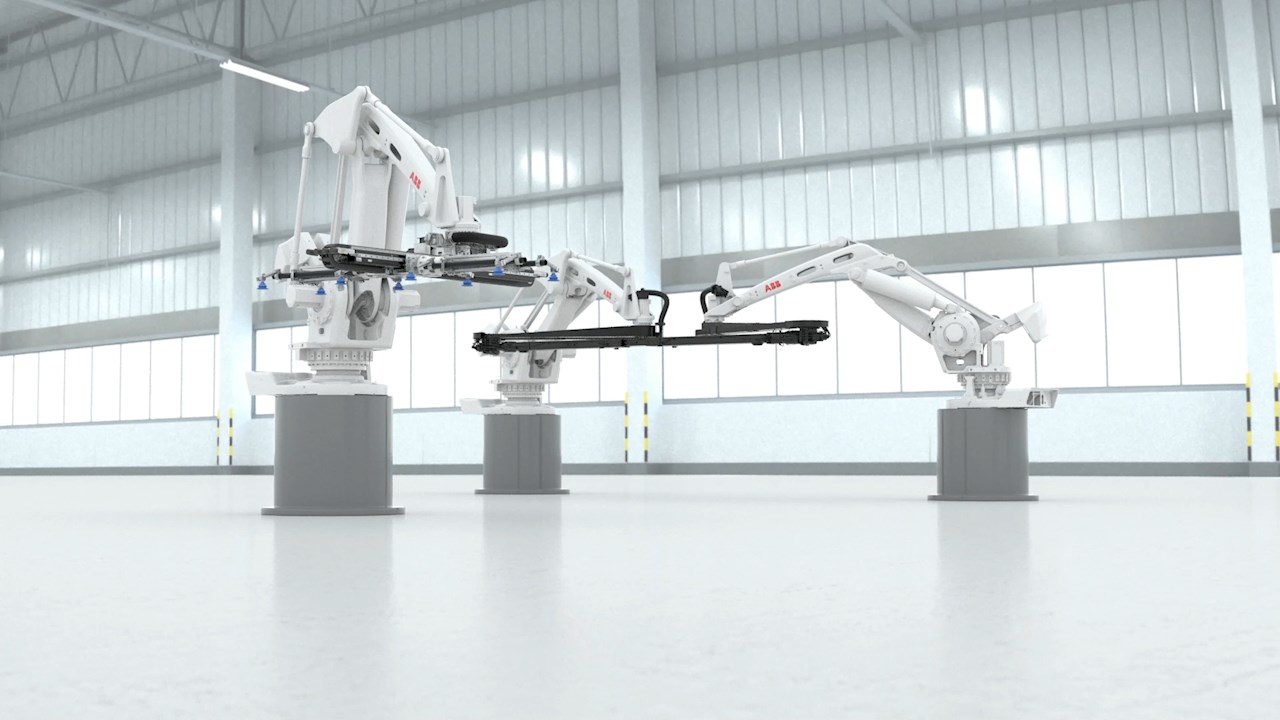

Two IRB 760PTs can be combined to work in tandem across 10 axes with a production output rate of up to 16 parts per minute. This, according to ABB, creates what it claims is “the fastest robot-based solution on the market” for loading and unloading presses with long inter-press distance without the need for press modification.

Furthermore, the IRB 760PT features a 3.18m reach, which, when coupled with a linear seventh axis, or with a Twin Xbar system, eliminates the need to reorient parts between consecutive stamping operations. This, said ABB, helps users optimise available space and save costs on investing in dedicated press automation.

ABB’s StampWare software is available on the robot’s FlexPendant. StampWare includes a graphical programming wizard that decreases the time needed to train the operator and robot programmer to enable the robot solution to be up and running quickly.