A flexible automated robot assembly line has been used to manufacture a new fleet of sustainable grocery delivery vans for major UK supermarket retailer Asda.

Some 25 Blue Ocean Home Delivery Pods have been built at British engineering firm Penso’s brand-new 50,000ft2 production facility in Coventry.

The pods, which are manufactured from a blend of carbon fibre and recycled plastic, are purpose-built for 3.5-tonne light commercial vehicles and designed to tackle issues facing last-mile logistics fleets, such as reducing carbon footprint, driver shortage, tighter legislation, imminent technology advances in alternative fuels and increasing customer demand.

Installation of the flexible automated robot assembly line and delivery of the 25 units to Asda represents the culmination of more than 10 years of research by Penso and a £16.3m investment – half from Penso and half from UK government matched-funding via the Advanced Propulsion Centre and Innovate UK.

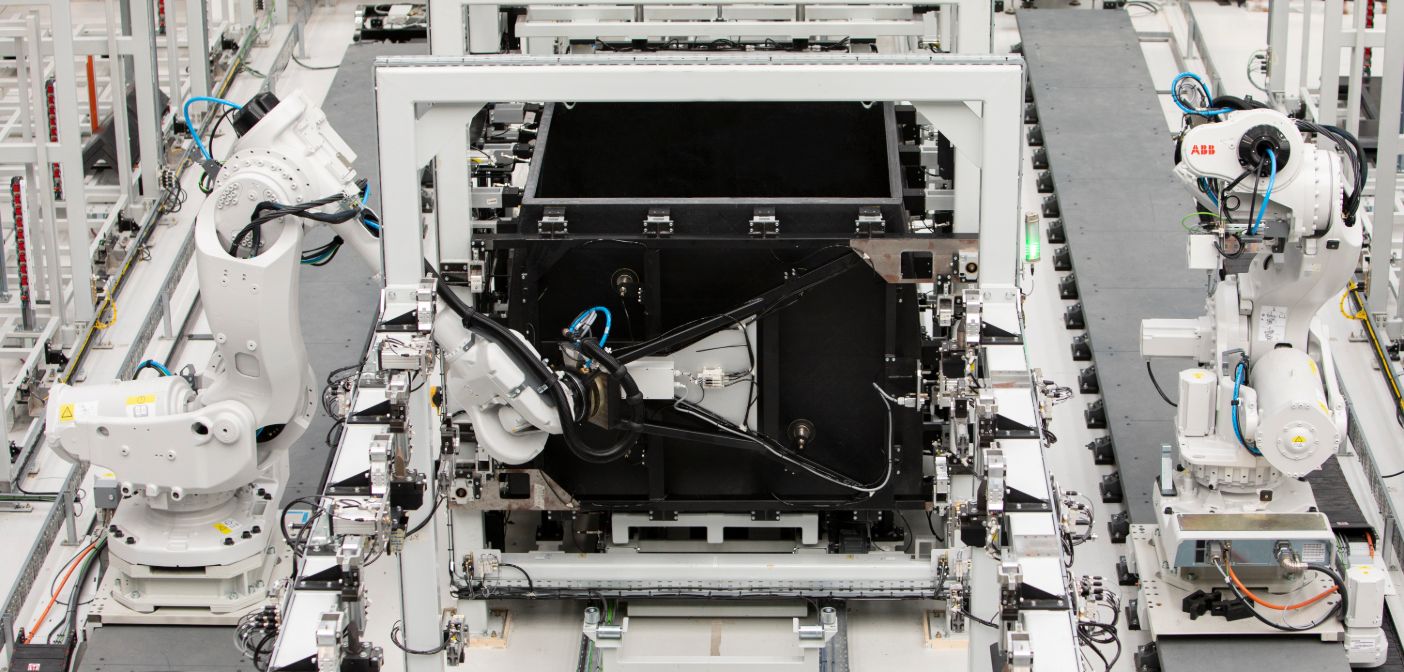

The line, which uses industrial robots from ABB – comprising two 7-axis robots for transport and positioning and two static robots for adhesive dispensing, can produce a finished pod every 42 minutes.

What’s more, the panel curing process is automated using pressure and temperature control algorithms, and the finishing and machining work is undertaken using an automated 5-axis CNC routing centre. The bonding and jigging activity is also automated using a CNC-controlled series of framing fixtures.

Penso will initially produce two models – a temperature-controlled e-Grocery Pod for supermarket deliveries, and a dry freight e-Delivery Pod for logistics and parcel delivery firms, based on a Luton van.

Ultimately, 30 different pods will be offered including medium- and high-roof van body variants with a choice of single and double compartments, twin rear doors and side-door loading configurations, plus tail-lift options. These will be built across different wheelbases and vehicle platforms to suit a variety of applications and fleets.

Asda’s new e-Grocery Pod fleet has been supplied on a 3.5-tonne medium wheelbase, front-wheel-drive, Mercedes-Benz Sprinter chassis. Like the-Delivery Pod, it offers the ability to carry the same weight of goods in two journeys that a conventional vehicle delivers in three.

Daniel Hurcombe, managing director of Penso, said: “By introducing new materials and processes to the commercial vehicle sector, we can offer home delivery fleets the potential to carry a lot more goods in fewer journeys which is something they have wanted to achieve for a very long time.

“Our new facility is designed to build up to 10,000 each year, and the plan is to ramp up production steadily over the next five years.”

The pods are designed to be compatible with diesel, electric and hybrid models – ensuring the design is future-proofed for next-generation vehicles.