RND Automation, a provider of robotic packaging solutions, has integrated several Epson Robots systems into its hydraulic valve assembly machine.

These include Epson’s T3 All-in-One and G3 SCARA robots, as well as its C8 compact 6-Axis robots, which the company describes as a “fully customised and complete automation solution for demanding assembly operations at an affordable price”.

RND has incorporated the Epson SCARA and 6-Axis robots with rotary and linear indexers and machine vision for its hydraulic valve assembly machine.

RND said it chose the Epson T3 All-in-One SCARA robot for its “fast installation, low cost [US$7,495] and all-in-one design, with a built-in controller”, making it suitable for simple pick and place operations, and the G3 SCARA robot for its “increased speeds and inertial loads for the more demanding stations”.

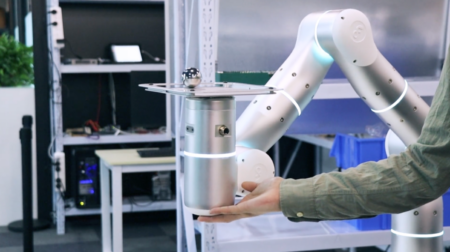

The company added that the Epson C8 6-Axis robot was also selected for its “slim line design” and “wide range of motion”, which makes it suitable for applications with limited workspace.

Sean Dotson, president and CEO, RND Automation, said: “Leveraging the Epson robots’ precision and fast cycle time, our hydraulic valve assembly machine can produce one valve every 6 seconds solving our customer’s need to ramp up volume and improve product quality.

“Also, due to the compact workcell design, our customer freed up a large amount of manual production floor space.”

The hydraulic valve assembly machine is based on RND’s modular assembly platform, which utilises a linear motor puck technology to move the parts from station to station.

With the modular design, each station can carry out a new component assembly or inspection.

The Epson T3, G3 and C8 robots pick parts ranging from nuts, housings, and springs, to adjustment screws and hex bodies, assembling them into the awaiting pucks. A leak test is performed at the final station and finished valves are exited from the machine.

Gregg Brunnick, director of product management for Epson Robots, added: “With 20 years of experience in industrial machinery design, RND is well equipped to provide customers with production-ready automated equipment that can help cut labour costs and improve quality and production rates.

“The company’s team of experienced engineers and designers make sure to set customers up with custom RND/Epson Robots solutions that are efficient, robust, and reliable.”