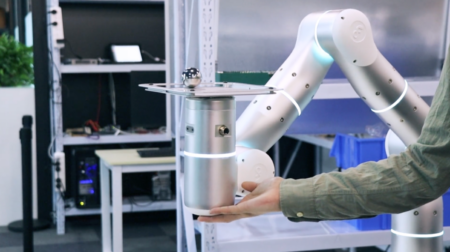

Mitsubishi Electric has extended its MELFA articulated arm and SCARA robot offering to include a range of delta robots.

The new robots combine Mitsubishi’s servo technology with the latest mechanicals from e-F@ctory Alliance partner Codian Robotics for higher speed pick and place operation and simple set-up and programming.

Machine builders can choose to build a delta robot solution around either Mitsubishi Electric MELSEC PLCs or MELFA robot controllers.

With MELSEC PLC, users can take advantage of the iQ Monozukuri Handling solution, which combines Mitsubishi Electric iQ-R series PLC with servos, HMIs and a handling application package and control programme.

In this way, iQ Monozukuri Handling configures the mobility and functionality of the delta robot.

General automation components can be used and the delta robot control can be integrated with other parts of a given process.

Machine builders can also use Mitsubishi Electric’s MELFA robot controllers and programme the delta robot using the company’s RT-Toolbox software.

This uses the same programming methodology as a conventional robot system as it is the same platform tool used to programme Mitsubishi Electric’s ranges of articulated arm and SCARA robots.

Solutions can be based around the Codian D2 or D4 ranges of robots.

D2 robots are offered in either two or three axes, with maximum speeds of 250 picks per minute, payloads up to 100kg (220 lb) and a maximum working envelope of 1,500 x 430mm, depending on model.

Codian D4 robots are offered in either three or four axes, with maximum speeds of 200 picks per minute, payloads up to 35kg (77 lb) and a working envelope of up to 1,600 x 350mm.

Barry Weller, Mitsubishi Electric robot product manager, said: “Codian Robotics has been a member of the Mitsubishi Electric e-F@ctory Alliance for several years and is an acknowledged market leader in the design and manufacture of this type of robot.

“The products are well developed, and the innovative parallel kinematic technology is a perfect match for the precision and performance of the Mitsubishi Electric range of servo drives and motors.

“Interest has already been strong, particularly from established Mitsubishi Electric automation users as the system integration aspect is so straight forward.”

As well as offering low noise levels of below 68 decibels, these delta robot solutions are sealed to IP65 as standard, preventing ingress of dust and water and offering protection from low pressure water jets from any direction with an option for IP69K for use in F&B applications.