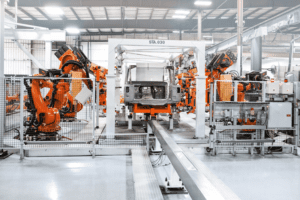

Kuka Systems has won three new orders for automotive assembly line conversions.

Within the scope of two new orders, Kuka will convert an assembly line for a European vehicle manufacturer to integrate a new product family of differentials.

It will also implement a new line for engine block assembly, including system linking via transportation using driven workpiece carriers.

Kuka said it received both orders, which are reportedly in the “single-digit million euro range”, in the fourth quarter of 2019.

In the first quarter of 2020, a third order in the “single-digit million euro range” followed from a European automaker, for the integration of a new motor variant into an existing assembly line.

Timo Heil, vice president, assembly and test, Kuka Systems, said: “Here at the Kuka site in Bremen, we have been developing automotive assembly systems for over 35 years and testing systems involving the powertrain since 2007.

“We know the technologies required for automated assembly tasks and have comprehensive process knowledge.

“With this expertise, we help our customers modernise their assembly lines in the shortest amount of time and thus make them more flexible.”

Want to read more stories like this?

https://www.roboticsandautomationmagazine.co.uk/bmw-places-huge-industrial-robot-order/

https://www.roboticsandautomationmagazine.co.uk/robots-to-bolster-bmw-production-lines/

https://www.roboticsandautomationmagazine.co.uk/ford-deploys-universal-robots-cobots-on-fiesta-production-line/

https://www.roboticsandautomationmagazine.co.uk/kuka-unveils-fully-automated-fast-food-machine/

https://www.roboticsandautomationmagazine.co.uk/kuka-launches-new-robot-for-medium-payload-category/