Kindred, part of Ocado Group, has released the results of an 18-month beta test of its robotic induction system, named Induct, which is powered by artificial intelligence (AI).

According to Kindred, Induct was able to automate the induction of more than one million items at a 95% accuracy rate and was tested at a global logistics centre.

“This was the most intense and demanding real-world scenario we could test in and Induct emerged triumphant,” said Marin Tchakarov, CEO of Kindred.

“By succeeding here, we have proven Induct can be successfully deployed now in any type of facility that uses induction.”

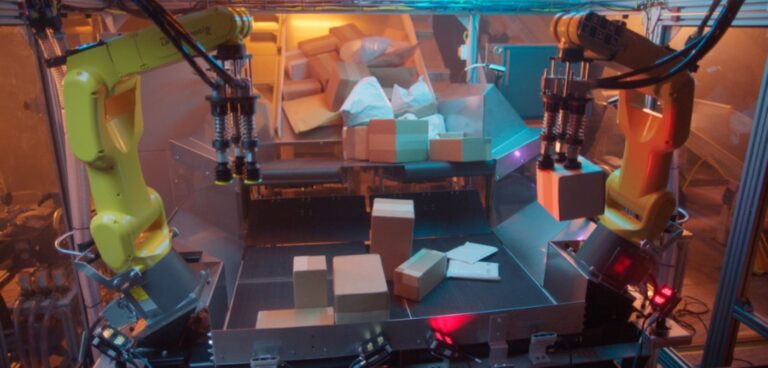

The solution was designed as a high-speed robotic workcell built on Kindred’s proprietary Core/AutoGrasp AI platform.

It works through a combination of machine vision, grasping and manipulation algorithms to automate the induction of items, including boxes, envelopes, parcels and packages.

The company claims that, as they are powered by Kindred’s reinforcement learning-based AI algorithms, Induct workcells can continuously learn and become smarter, faster and more efficient over time.

Some of the KPIs Kindred highlighted from the trial included: one million packages processed through the induction cycle; an average of 1,800 picks per hour (PPH); 2,000 PPH at its peak; and 95% accuracy in the placement of items on a moving conveyor system.

Induct can also be offered as a Robots-as-a-Service (RaaS) model.