BMW is to introduce autonomous machine-vision software to its engine plant in Austria.

As part of the automotive OEM’s aim to use digitalisation to improve production processes, the new solution will inspect the quality of the engines.

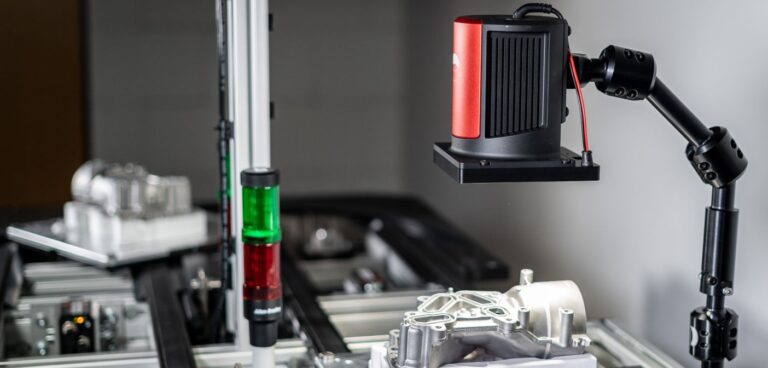

Developed by German-Israeli company Inspekto, the Inspekto S70 software can memorise characteristics and flag anomalies.

According to Inspekto, the product is self-learning, self-setting and self-adjusting, making it fully autonomous and enabling quick integration, a ‘plug and inspect experience’ and shorter training process.

David Bricher, innovation and digitalisation expert at BMW, said: “One of the most interesting characteristics of the Inspekto S70 is its ease of installation.

“At BMW, one of our main targets is to bring the potential of AI closer to the production field. We have to get rid of the mystique that surrounds the technology — people have to be able to say: I work with AI.”

Prior to the deploying Inspekto S70, BMW said it had reservations about some conventional machine-vision solutions, which suffered from pseudo-errors.

These errors occur when a solution flags a defect component that actually meets specifications, meaning any flagged items need to be rechecked manually.

Bricher added: “The most problematic issue is that with increasing pseudo-defect rates, employees at the repair station could let their guard down and assume that an actually defected item is good.

“BMW is not willing to compromise on quality and we want to prevent this scenario at all costs.”

The company set up a Start-Up Garage to find intuitive quality assurance technology and selected the Inspekto S70 system can be set up by any employee.

Following the success of a pilot scheme featuring four Inspekto S70 systems, the technology is now operational in a connector with small, hardly-visible components and a fuel pipe.