AMP Robotics, which uses AI and robotics to recover commodities reclaimed as raw materials for the global supply chain, is extending its ability to identify and pick recyclables at brand level by working with consumer packaged goods (CPG) companies to recover higher rates of these materials.

One of AMP’s first corporate partners is consumer beverage giant Keurig Dr Pepper (KDP) in support of its introduction of recyclable K-Cup pods. Following KDP’s conversion of its coffee pods to polypropylene, a sought-after plastic for recycled materials, the companies worked together to equip AMP’s robotics systems to identify and sort K-Cup pods in recycling facilities. All of the K-Cup pods KDP produces are now recyclable.

Monique Oxender, chief sustainability officer, Keurig Dr Pepper, said: “Our move to recyclable plastic is a critical first step, but to make greater strides toward circularity, we need to improve acceptance and sortation so we can more readily incorporate recycled plastic back into our products and packaging. Recycling systems in the USA are diverse, and we need technology and infrastructure upgrades to improve the quality and quantity of recycled plastic available.”

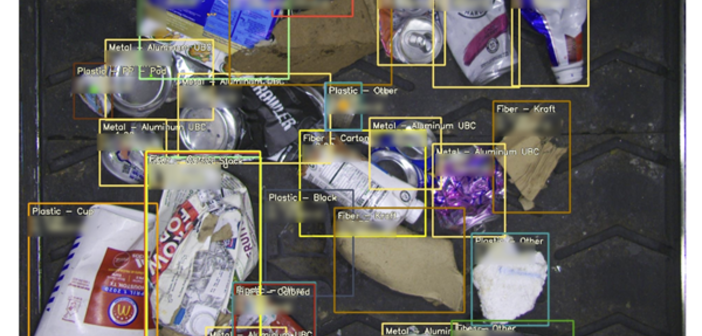

The AI platform that guides AMP’s robotics systems can differentiate objects found in the waste stream by colour, size, shape, opacity, brand, and more, contextualising and storing information about each item it perceives. AI and machine learning enable the robotic sorting of material as granular as a type of plastic at a pick rate of upwards of 80 items per minute – more than two times as fast as human sorters, and with greater accuracy and consistency.

According to AMP, this process produces a higher quantity and quality of plastic that suppliers of polypropylene resin can sell back to CPGs to create new packaging. The company’s AI platform is designed to become smarter and more effective over time as the company deploys more robots. AMP can add subcategories of brand-level material to meet market demand and distribute the functionality to identify and sort it across its fleet.

“Intelligent plastics sortation, powered by AI, robotics, and advanced data analytics, can have cross-value chain impact and direct benefits to plastic waste generators, sorting facilities, recyclers, and consumer packaged goods companies,” said Rob Writz, director of business development for AMP Robotics. “AI-guided sortation ensures a higher-quality end product that isn’t contaminated by other materials, and a larger volume of recycled material. Collaboration across the recycling value chain will turn product and packaging waste back into the inputs for future manufacturing while growing and strengthening our recycling system.”

AMP has also opened a new 40,000ft2 test facility in Colorado to explore expanded applications of its technology with the goal of increasing the feedstock of recycled content for CPGs and container producers. It has been designed to help prototype new, economical ways to ensure recyclables are recycled, even for low volumes that historically have not been economical for recovery. By lowering the cost of recycling marginal volumes, AMP said it aims to maximise resource recovery and quality for the manufacturing supply chain.