Researchers at Liverpool Hope University are developing an AI-based system that could reduce the amount of waste the UK sends to landfills.

The low-cost sorting system uses computer-vision cameras trained to identify household objects on a conveyor belt, enabling a robot to sort materials.

The researchers said they have been able to prove the method to a high degree of accuracy and have produced the classification system for less than £100, giving the system the potential to be adopted across the world.

In a new report, Dr Emanuele Lindo Secco, of Liverpool Hope’s School of Mathematics, Computer Science & Engineering, and co-author Karl Myers, wrote: “Due to rapid urbanisation, increasing population and industrialisation, there has been a sharp rise in solid waste pollution across the globe. Do we have the capacity to handle such an increase in waste?

“The answer to the question is no – at present we do not have the capacity to handle an increase in waste and moreover we do not have the capacity to handle the waste we are retrieving now.”

The researchers added that efforts must be made to streamline the waste sorting process and said intelligent retrieval of waste could ease the pressure on Material Recovery Facilities (MRFs).

Waste is currently sorted using magnets, eddy current and by hand-by-human operatives. Secco said: “Operatives have to continually monitor the materials coming from each stage to remove and sort the materials the mechanical process misses.”

Secco added that this means the cost of recycling is inherently higher due to the human resource cost. As MRFs move away from labour-intensive sorting, systems such as this can move in.

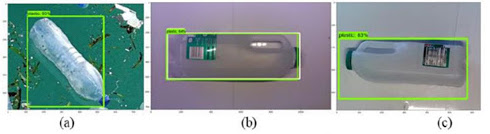

The study used a ‘Raspberry Pi’ computer, often used to teach children code, and married it to a high-resolution camera. Through machine learning the computer was programmed to identify and sort five different types of waste; paper, glass, plastic, metal and cardboard.

It does this through access to a database of 3,500 different images of rubbish, courtesy of Google and a resource called ‘TrashNet’. Through ‘transfer learning’ training, the system’s knowledge of labelling trash advanced as the project continued.

As reported in its findings, the team was able to hit a 92% success rate, which is enough to make the system viable for commercial use.