Nissan has announced that it is using lithium-ion batteries from its electric vehicles (EVs) to power its range of automated guided vehicles (AGVs)

Working in partnership with 4R Energy, Nissan has repurposed batteries from the first-generation Leaf EV, which are no longer powerful enough to run a car.

Initially, Nissan’s engineers took three modules from a 24kWh battery pack and repackaged them to fit inside an AGV.

The Japanese automotive OEM then expanded the idea by using repurposed battery modules, instead of new ones, to power the AGVs.

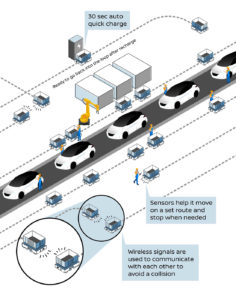

According to Nissan, the AGVs powered by the lithium-ion batteries, new or repurposed, charge faster and workers are no longer required to take out the batteries to plug them in.

The AGVs stop momentarily at the charging station along their route and incrementally top up at each passing.

Furthermore, the repurposed Leaf batteries last longer than lead-acid batteries, which are typically replaced every year or two. According to Nissan, the repurposed Leaf batteries are expected to last seven to eight years.

The Japanese carmaker said fewer batteries means less impact on the environment and another step toward being carbon neutral.

“Our customers benefit too. When used EV batteries become more valuable, trade-in prices rise” said Masashi Matsumoto, who promotes the development of AGVs at Nissan’s production technology research and development centre.

In addition, Nissan is researching connected technology to allow the AGVs to stay in contact with the computer handling their movements.

“Using our unique electric-driven and autonomous driving technologies to improve AGVs will bring major innovation to our factories,” said Matsumoto. “The supply of parts in factories is entering the age of electrification and automation.”

Currently, Nissan has over 4,000 AGVs operating at its car factories across the world, of which there are 700 alone at its Oppama plant, south of Tokyo.