The first three spin-out companies have been launched from a government-backed knowledge exchange partnership designed to revolutionise the creation and uptake of early-stage agri-tech opportunities.

Robotic mushroom picking, strawberry yield forecasting and new bio-based materials to drive down the carbon footprint of car manufacturing are the focus of the first three companies to emerge from projects funded by Ceres Agri-Tech – a partnership between five UK universities and three agricultural research institutes.

Ceres spin-out Agaricus Robotics is developing a robot that can harvest even the most challenging dense clusters of mushrooms.

“In the UK alone, approximately 4,500 people are required every day to pick mushrooms – with labour costs representing a third of total production costs,” said Agaricus Robotics founder Bashir Al Diri.

“It takes up to six months to train a picker and their skill determines the productivity of each mushroom bed. But our patented intelligent mushroom harvesting robot can pick whole crops without bruising the mushrooms and will lead to 20-30% yield increases from optimised 24/7 harvesting 365 days a year. The backing of Ceres is proving invaluable as we now accelerate the commercialisation of our technology.”

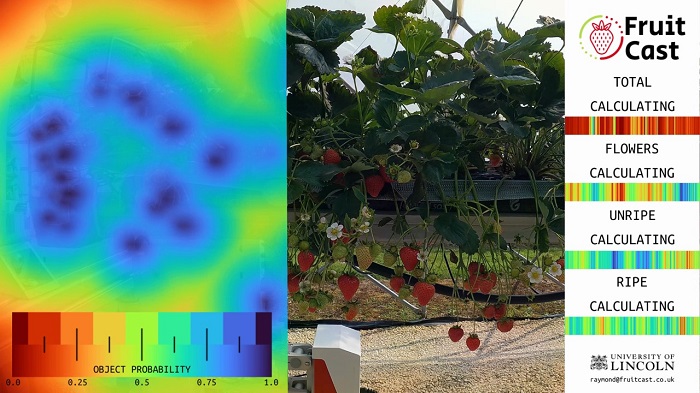

Additionally, FruitCast is focused on strawberry yield improvements, with a yield forecasting system based on AI-enabled data analytics. Image data from hand, vehicle or robot mounted cameras is used to measure individual fruit numbers, along with the weight and maturity state of millions of berries each day. This data is combined with weather forecasts in algorithms to predict yield with unrivalled accuracy six weeks ahead of existing systems.

“The UK produces 120,000 tonnes of strawberries each year, with a retail value of £659m,” said Raymond Kirk, Fruitcast founder.

“Predicting the timing and yield of strawberries is critical for the industry – but extremely difficult to do accurately. Thanks to the support of Ceres, we are creating a system that will not only benefit strawberry growers through improved sales but also reduce supply chain friction and crop waste.”

The third of the initial batch of Ceres spin-out companies is Cellexcel, which has developed an industrial-scale patented process to make water-resistant materials from flax. The global market for composites – materials made from resin-reinforced fibres – in car manufacturing is predicted to reach nearly £20bn by 2024. But the most popular composites, such as fibreglass and carbon fibre, are non-renewable and energy intensive to produce.

“Replacing fibreglass and carbon fibre with renewable bio-based materials like flax promises to increase sustainability and reduce carbon footprints, as well as improving vehicle safety – as bio-composites do not shatter on impact,” said Cellexcel co-founder Richard Stephenson. “However, currently available flax-based composites are not water resistant and therefore cannot be used on car exteriors – severely limiting their applications. With the help of Ceres, our novel process is now set to drive down the carbon footprint of car manufacturing and add value to agricultural products and agricultural waste.”

Led by Cambridge Enterprise, the commercialisation arm of the University of Cambridge, Ceres was launched in 2018 – funded by Research England – to commercialise innovative agri-tech based on university research. The other partners are the University of East Anglia, the University of Hertfordshire, the University of Lincoln and the University of Reading, as well as the National Institute of Agricultural Botany, Rothamsted Research and the John Innes Centre.