Fieldwork Robotics has announced the development of a digital simulator of its raspberry picking robot following a £145,000 grant from Innovate UK.

The funding aims to mitigate the effects of the coronavirus pandemic on the company via a simulator that will allow its engineers to work remotely during lockdowns and optimise internal processes to reduce prototyping costs.

An alpha prototype for manufacturability of its raspberry-harvesting robot is expected to be ready for trials in spring 2021.

This latest investment follows a continuity grant of £84,000 from Innovate UK in September to support Fieldwork’s costs, including raw materials, which have risen during the pandemic.

As previously reported by Robotics & Innovation, Fieldwork won a £547,250 Innovate UK Industrial Strategy Challenge Fund grant in April 2019 to accelerate development of its technology.

Rui Andres, chief executive officer, Fieldwork Robotics, said: “Innovate UK has been following our work closely, and we are very grateful for the continued support.

“This grant will allow us to build a tool that will save us time and money, while mitigating the effects of Covid-19.”

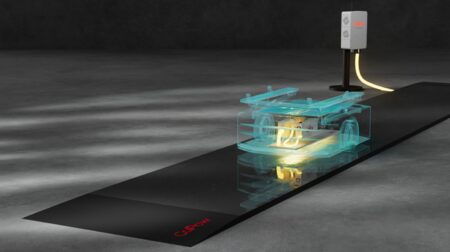

Furthermore, the development of the simulator will also see Fieldwork work with industry partner Bosch once more.

Bosch entered into an agreement to work with Fieldwork Robotics in July this year to optimise the company’s soft robotic arms and develop software aimed at reducing the arms’ cost and increasing their speed.

Andres added: “The Bosch collaboration has been invaluable, and we are very keen to keep developing our work together.

“And finally, this grant helps to reduce our carbon footprint, minimising the amount of plastic we require for the development of our robots.”