Agri-tech start-up Crover has developed a burrowing robot which ‘swims’ through grain bulks to ensure crops are stored more efficiently, and as a result will be joining the National Robotarium, an Edinburgh-based centre for robotics and artificial intelligence research.

The t-shaped robot, which is being funded by Innovate UK, Scottish Enterprise and private funders, has been designed to offer those working with grain better insight into the environmental conditions of grain crops, such as wheat and barley, when stored in sheds or silos.

Traditional processes for store checks, which rely on manual sampling with a spear, are often time consuming, labour intensive and potentially hazardous, according to Crover.

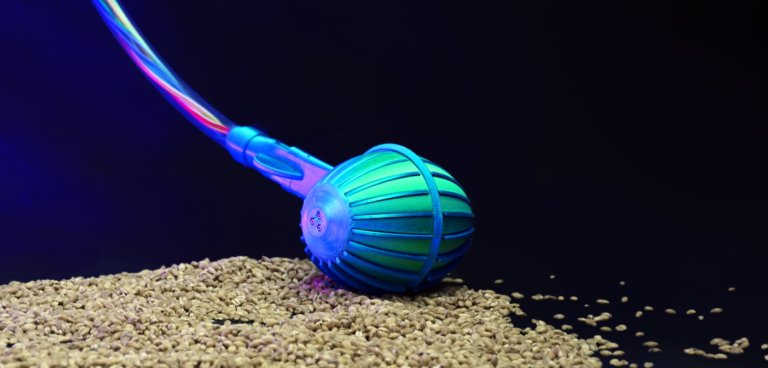

In response to these challenges, Crover has equipped its machine with moisture and temperature sensors, with the robot using two domed-shaped wheels to propel itself through grain or other material in a bulk stack.

After ‘surfing’ through the grain, the machine then feeds back analysis and data to a dashboard with the aim of giving users a more accurate understanding of the grain’s condition.

Lorenzo Conti, founder and managing director of Crover, said: “Traditional methods like spear sampling grain are time-consuming and laborious and quite often impractical and dangerous. In practice, grain storage operators are advised to sample bulk stacks at every 50cm intervals.

“The reality is that, if done manually, someone could spend the best part of a week carrying out a single store check depending on the size of their crop load.

“Our device is designed to be controlled from one spot and saves whoever is operating it many hours of work as well as improving accuracy. The robot can ‘swim’ through the grain quickly generating a 3D map of temperature and moisture across the stack.

“This kind of insight can help people like farmers to better understand the condition of their grain and make informed decisions earlier like increasing ventilation or taking pest control measures.”

Some of the major factors affecting grain storage Temperature and humidity have a profound impact on grain storage and can contribute to the infestation of mould or insects which cause farmers to destroy significant portions of their stored crops.

It is estimated that up to 30% of commodity grain is lost from the supply chain globally every year as a result.

The Edinburgh-based start-up has recently taken up residency at the National Robotarium, a pioneering new £22.4 million research facility which officially opened its doors in September 2022. Informed by sectoral needs, the facility works collaboratively with partners around the globe to define, develop and resolve industry challenges through the application of robotics and AI. Crover will benefit from the National Robotarium’s incubation facilities, state-of-the-art labs and engineering expertise.

Steve Maclaren, chief operating officer at the National Robotarium, said: “The National Robotarium was launched with a mandate to assist all types of partners to accelerate research from laboratory to market, reduce cost and risk, increase opportunity and, ultimately, pave the way for the UK to take a global leadership role in AI and robotics technology.

“Innovations like Crover’s grain storage device – which could help solve a global problem for the world’s agriculture sector – are a great example of this mandate in action.

“The National Robotarium continues to be a leading collaborative hub, bringing together academics and global companies. Working with tenant companies like Crover, we want to provide a catalyst for entrepreneurship, and deliver sustainable economic benefit to the whole of the UK, its industries and society.”

The National Robotarium is part of the Data-Driven Innovation initiative, supported by £21m from the UK government and £1.4m from the Scottish government.