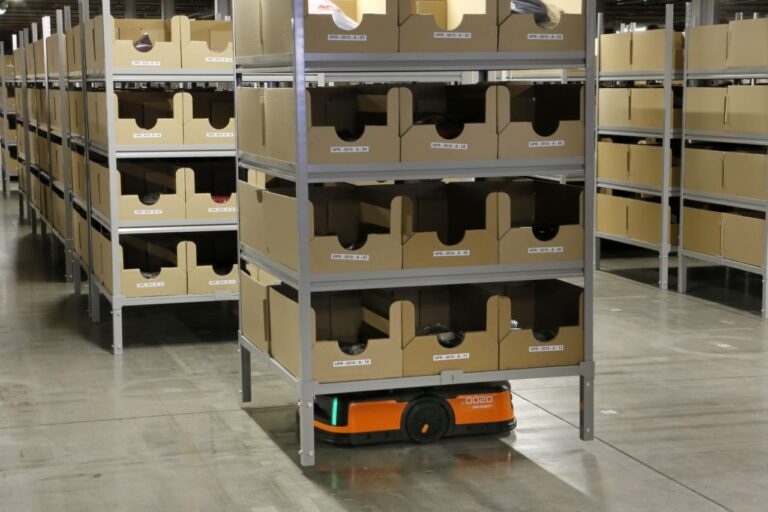

IntraLogisteX 2020 exhibitor Hikrobot has launched a range of mobile robots for warehousing applications to the UK and Europe through Cranfield–based systems integrator Invar Systems.

The automated guided vehicles (AGVs) can be supplied as part of a complete ‘smart warehouse’ solution to provide automated transport and goods-to-person order picking operations.

Systems benefits reportedly include increased accuracy and expedited order fulfilment; reduced cost-per-pick and a fast ROI; flexibility and scaleability that allows users to start from a small base and add units as required – avoiding redundant capacity at initial installation – high density storage that maximises floor space; no need for bolted down racking with conveyors and stacker cranes; and no major infrastructure changes required.

The low-capex solution is suited to sectors such as e-commerce, food and beverage, apparel, automotive, aeronautical, manufacturing and third-party logistics.

Frazer Watson, head of sales, Europe, at Invar Systems, said: “Fast fulfilment demands agile and efficient picking processes.

“This intelligent mobile robot solution offers all the speed and flexibility that e-commerce businesses, and other sectors, have been looking for when faced with the dual challenges of responding to growing order volumes, with dwindling labour resources.

“This technology has the intelligence and inherent simplicity to revolutionise the warehouse.”

A complete system features an AGV, robot control system and an intelligent warehouse management system. It also supports integration with ERP systems.

Controlled wirelessly, the battery-powered AGVs use inertial and visual navigation to achieve accurate positioning for loads.

QR labels are used for the routing, which, according to Hikrobot, minimises installation, set up and operation costs of the system.

The robots can adjust to existing warehouse environments, which can be mapped into the system.

What’s more, each AGV has the capacity to carry load units – such as pick walls, rolls cages or other containers – of up to 1,000kg.

According to Hikrobot, the goods-to-person model increases efficiency by eliminating unnecessary walking and searching for items.

The interactive picking station uses on-screen instructions and pick-to-light technology to guide pickers to attain pick rates in excess of 600 picks per hour.

Furthermore, battery charging stations can be strategically managed to ensure robots are charged when needed.

Hikrobot’s has been successfully piloted in the UK at an international fashion brand and is currently being expanded in a phased programme.

Want to read similar stories to this?

IntraLogisteX exhibitors announce UK partnership

OW Robotics to launch updated goods-to-picker solution at IntraLogisteX

DHL Supply Chain and Locus Robotics expand partnership

Asics implements mobile picking robot

DB Schenker implements automated forklift

CEVA Logistics deploys cobots at Dutch warehouse

Boston Dynamics unveils integrated warehouse automation solution

![]() Hikrobot (stand 330) will be at IntraLogisteX 2020, which will take place on 28 and 29 July at the Ricoh Arena, Coventry. The exhibition was rescheduled in the light of the coronavirus pandemic.

Hikrobot (stand 330) will be at IntraLogisteX 2020, which will take place on 28 and 29 July at the Ricoh Arena, Coventry. The exhibition was rescheduled in the light of the coronavirus pandemic.