Maria Highland delves into the tangible benefits in sight for AR-equipped industrial facilities…

ABI Research’s Augmented and Mixed Reality Market Data report estimates the augmented reality (AR) market will surpass US$140bn (£106bn) in total market value in 2025. More specifically, industrial AR is set to reach US$70bn (£ 53bn) by 2025 due to a jump in the uptake of AR smart glasses and mobile devices as a means of bridging the gap created by Covid-19.

“The pandemic did not create the need for digitisation, but it certainly accelerated it,” says Eric Abbruzzese, research director, augmented and virtual reality at ABI. “As a high-value element of digitisation, AR adds a visual element to a data-heavy system that can sometimes devalue the human worker. It brings the worker back into the equation and creates a synergy between worker and IT/OT systems where each component benefits from the other.”

If Covid has taught us anything, it’s that the value of operations lies with the workforce. Businesses should be looking to help their staff perform at their peak and AR is a good place to start.

Peak performance

“Smart glasses connect workers to both machines and enterprise management software – hands-free. They can deliver full interaction and communication, including images and audio, between workers, managers and software,” explains Vuzix in its white paper, Optimising Warehousing & Logistics Operations. This is useful for picking: “The wearer never has to refer to a printed pick or count sheet – it’s right in front of their eyes. They can provide real-time feedback to ensure correct picks are made and inventory counting can be done on-the-f ly while picking. If they spot an error, they can instantly ask a question or refer to other documents – and so can their supervisor, at the same time,” Vuzix explains.

“Workers can give voice confirmation of order completion, talk to colleagues at the loading bay, scan return tags,” it adds. Likewise, smart glasses can also be used for navigation, allowing optimal routes to be identified, thereby minimising the amount of time employees spend walking around warehouse or manufacturing facilities, and improving efficiency. For example, using a pick-by-vision solution, logistics company Gies was able to improve order picking efficiency by 30%.

Likewise, after a pilot using AR glasses, DHL saw a 25% increase in total picking efficiency along with increased productivity and reduced error rate – particularly important as its warehousing operations such as packing, storage, and put-away always accounted for around 20% of its logistics expenses.

Another benefit of AR is the capability to try out different facility layouts before going through the arduous process of product storage and semi-permanent object relocation. AR enables full-scale analysis and staff input to ensure that the new layout is ergonomic, efficient and enables troubleshooting. As a result, businesses can save time, money and planning effort – as well as peace of mind that the most efficient layout has been selected, ensuring efficient operations and much faster turnaround times.

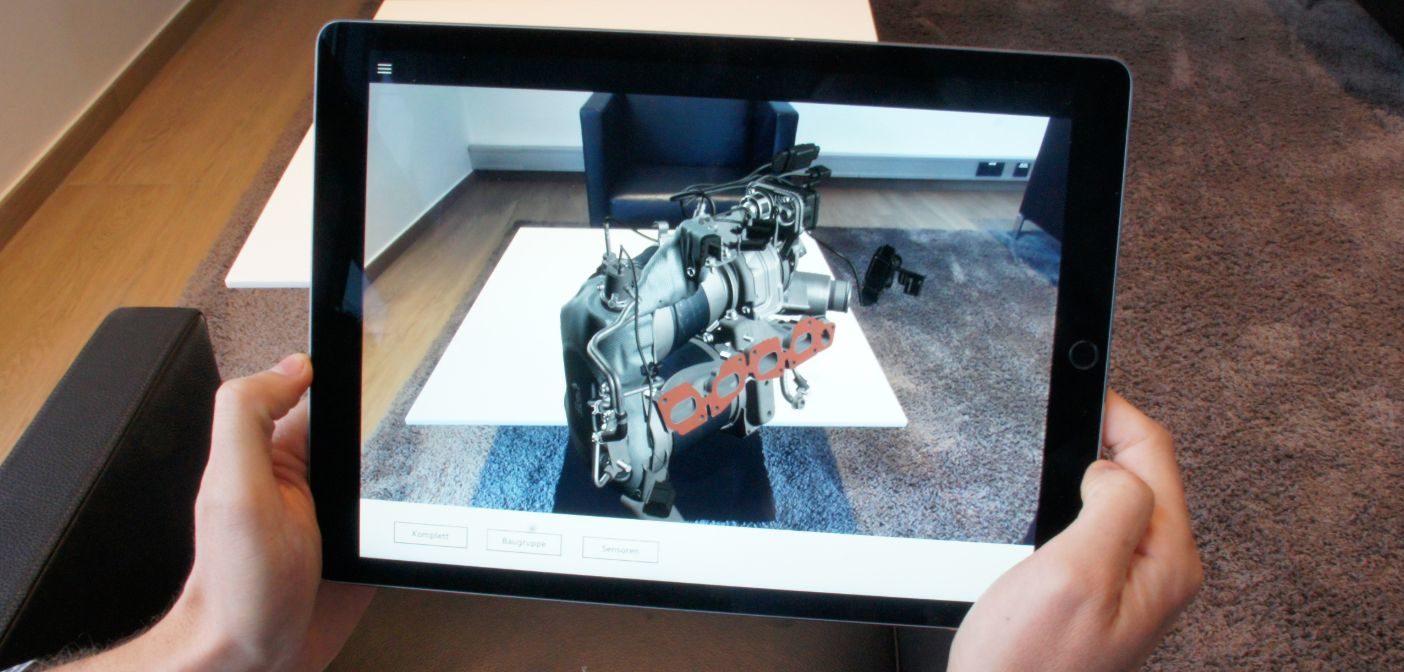

German carmaker Audi uses AR to plan complex manufacturing processes, cutting costs in the process. Using three-dimensional holograms, it can see a virtual presentation of objects in the environment, eliminating the need for prototypes. The same image is shown across multiple AR devices and can be interacted with in real-time, facilitating collaboration regardless of location. Image sharing also helps to simplify discussion and decision-making somewhat, in doing so creating further cost savings.

Six steps to invest

PTC’s white paper, Getting Started with Industrial Augmented Reality Solutions, outlines six steps to take when looking to invest in AR. It explains that “implementing an AR solution requires proper planning, including identifying the technology that will best fit your needs, as well as how it will be adapted into existing processes.

“Relative to other operational technology innovations, AR has a much faster time-to-value that can be achieved with little-to-no programming expertise, depending on the solution. But like any industrial technology, AR must be implemented properly for successful adoption.” PTC suggests starting with determining pain points and assessing how AR can help address them. It recommends working with industry and to “take a collaborative approach to implementation, quality control, process development and project evaluation”, which also includes iterating with a test audience to fine-tune any unclear parts.

PTC also highlights the importance of training employees and centring the user experience. “It’s important to design experiences that reflect user intent, and to involve them early and often in the testing and development phases,” notes PTC. Likewise, PTC recommends measuring results as soon as possible. “Gathering a pre-AR baseline with the key metrics you’ve identified will help you connect your results to immediate business value and allow you to better track progress over time,” it suggests. Setting short-term checkpoints will also help prove continual progress, acting as a morale booster for both the team and stakeholders.

Far from reality?

“AR is viewed as a technology still in its infancy but with a very bright future ahead,” believes ITRtrex Group emerging tech analyst, Yelena Lavrentyeva. In her blog, Augmented reality cost: key factors and real-world examples, she noted its most notable debut being in 2016 with Pokémon Go but feels there is still much further to go: “We’ve barely scratched the surface. Most AR solutions today are designed as mobile AR apps. However, the rise of WebAR should change this trend as it makes AR experiences accessible from a web browser, with no app downloads needed. Head-mounted displays and smart glasses are expected to be the next megatrend,” she adds.

Tony Sol, business development manager at application software company GBKSOFT concurs, explaining that an “AR device requires a particular application to work with it that can be designed by a development company to meet your specific business needs. But augmented reality can be seamlessly integrated into the existing work circle of your company.”

Bent into shape

Researchers at Imperial College London have designed a malleable robotic arm that can be guided into shape by a person using augmented reality (AR) goggles. The flexible arm can twist and turn in all directions, making it readily customisable for potential applications in manufacturing, spacecraft maintenance, and even injury rehabilitation.Instead of being constrained by rigid limbs and firm joints, the versatile arm is readily bendable into a wide variety of shapes. In practice, people working alongside the robot would manually bend the arm into the precise shape needed for each task, a level of flexibility made possible by the slippery layers of mylar sheets inside, which slide over one another and can lock into place. However, configuring the robot into specific shapes without guidance has proven to be difficult for users.

To enhance the robot’s user-friendliness, researchers at Imperial’s REDS (Robotic manipulation: Engineering, Design, and Science) Lab have designed a system for users to see in AR how to configure their robot. Wearing mixed reality smart glasses and through motion tracking cameras, users see templates and designs in front of them superimposed onto their real-world environment.

They then adjust the robotic arm until it matches the template, which turns green on successful configuration so that the robot can be locked into place.

Senior author of the paper, Dr Nicolas Rojas, of Imperial’s Dyson School of Design Engineering, says: “One of the key issues in adjusting these robots is accuracy in their new position. Humans aren’t great at making sure the new position matches the template, which is why we looked to AR for help. We’ve shown that AR can simplify working alongside our malleable robot. The approach gives users a range of easy-to-create robot positions, for all sorts of applications, without needing so much technical expertise.”

The researchers tested the system on five men aged 20-26 with experience in robotics but no experience with manipulating malleable robots specifically. The subjects were able to adjust the robot accurately and, though the pool of participants was narrow, the researchers say their initial findings show that AR could be a successful approach to adapting malleable robots following further testing and user training.