The farms of the future could see robots picking fruit, weeding without chemicals and autonomous vehicles providing vital crop data. But how close are we to seeing commercially viable robotic solutions on farms in the UK? Katie Searles investigates…

Advancements in technology that enable a robot to gently pick soft fruit have grabbed the attention of many in both the robotics and agriculture sectors. In November 2020, University of Plymouth spin-out Fieldwork Robotics announced the development of a digital simulator of its raspberry-picking robot following a £145,000 grant from Innovate UK. In September of last year, Fieldwork also revealed that it was working with vegetable producer Bonduelle to develop a second iteration of its picking robot to harvest cauliflower.

That same month, Saga Robotics, the Norway and UK-based developer of Thorvold, an autonomous and modular agri-robot platform, announced that it had raised £8.5m (€9.5m) to support future growth plans and further the development of its farming technology.

Whilst such projects sound impressive, Saga Robotics CEO Pål Johan From believes society is actually years away from seeing these kinds of robots entering the agriculture sector. “Most companies are struggling to get the speed and the reliability at a level where the technology will work on a commercial basis,” he says.

“There are a lot of strawberry-harvesting robots out there capable of picking single strawberries relatively well, but none of them are at a level today where they can actually make a difference to growers.”

From is not alone in his belief that there is a job to be done for all companies working in this space. Small Robot Company (SRC), the British start-up behind farmbots Tom, Dick and Harry, admits that agri-robotics is still a “very nascent industry”, while Jake Shaw- Sutton, senior robotic technician at the University of Plymouth, describes the current most successful robotic fruit-picking solution as no more than a “motorised deckchair”.

And according to Shaw-Sutton’s colleague, Yve Metcalfe-Tyrrell, SEI project manager, agri-tech and deep geothermal at the University of Plymouth, it’ll be years before farmers are in a position to adopt such technology. This outlook is echoed by Robin Jackson, director of Agri-tech Cornwall and the Isles of Scilly, a £10m initiative to drive research, development and innovation in country’ the agricultural sector.

“Unfortunately, the farming industry is risk adverse because it is a commodity industry. It is at the bottom of the supply chain. The profit margins can vary massively year on year, so farmers really want guaranteed technologies that work,” says Jackson. “This isn’t like the automotive industry, which innovates on a regular basis – tractors and ploughs haven’t really changed very much over the years, yet the technology that is needed in farming requires a big step change. It’s like agriculture 4.0.”

Data driven

According to Jackson, such technology will first need to be proven and to do so successfully will take “ideally three to five years”. Fortunately, such testing is already starting to happen across the UK.

One project leading the way is 5G RuralDorset, a £7m trial that aims to develop and prove a blueprint for rural-optimised 5G connectivity and trial the world’s first 5G-ready argi-robot for arable farms. As well as attempting to overcome the challenges of establishing rural connectivity, the project, held at Ranston Farms, will also explore how a 5G roll-out might be able to provide a necessary step-change in agriculture and close the rural-urban digital divide for farming and rural communities.

Sarra Mander, CMO of SRC, says: “There is a nexus of forces coming together – 5G, IOT, AI and robotics – to bring about so many new capabilities that we haven’t been able to do before but could enable certain aspects of farming technology to leap forward.”

Digby Sowerby, projects team manager at Wessex Internet, a participating organisation of the 5G RuralDorset programme, cites drones as one example of a new technology that could be used in a range of agricultural environments. With the ability to cover hundreds of acres and perform 3D field mapping and crop analysis, drones could provide vital data more effectively.

However, application of the technology does not come without its problems, as Sowerby explains: “Currently operators complete their exercise before taking the drone home and taking out a SD card, sticking that into the computer and spending a long time waiting for it to upload on their WiFi network.”

According to Sowerby, if these drones had a 5G rural network to tap into, the technology could offer real-time insights into crop health in a non-evasive manner.

Furthermore, he says that removing the need to return to a head office or base to access such data saves on costs. “Having data transferred in the field can have huge operational cost benefits.”

Pain points

Of course, costs are not the only savings farmers could stand to make as a result of the deployment of drones operating via 5G networks. Access to real-time data means crops could be spared from damage caused by pests if there is no delay in reporting such issues. A latency lag may not be an issue when fighting weeds but, when dealing with unwanted insects and animals, timing is critical.

This is why the first robot in the 5G RuralDorset project trial to test the data network is a slug-bot. Mander explains: “We think of slugs as moving slowly, but they’re relatively rapidly. If you find a problem-patch of slugs you won’t be able to come back the next day to treat it as the slugs will have already munched the crop by that point and gone off somewhere else.

“What we are looking to do in these trials is to first of all be able to identify a slug infestation and, secondly, treat it relatively contemporaneously. We are looking to try and do that with the same robot.”

Wessex Internet’s Sowerby also believes that access to real-time data would fix a range of problems for farmers. “There are a few pain points that we are trying to solve in agriculture, which are around essentially getting more information from the farm and being able to make more informed decisions based on that information.”

It was this lack of connectivity that led to the creation of Wessex Internet. Originally a farming business, the company diversified after the team was unable to find an affordable quote for getting fibre to the farm. Initially set up as a wireless network for local schools and local houses, the business has since grown into a full fibre network provider.

Currently, Wessex Internet is planting fibre into the ground across Dorset, Wiltshire and Somerset. “We’re really trying to reach those communities that are deemed unviable by the big network operators,” says Sowerby. The company has doubled in size in the last year as home schooling and home working has driven demand for a strong internet connection.

Covid catalyst

But it is not only Wessex Internet that has seen demand grow as a result of the coronavirus pandemic. As many industries adjust to new working norms, the agriculture sector is no different. Social distancing, a lack of available manual labour and additional scrutiny of hygiene has resulted in a willingness for businesses to try new solutions.

“We have seen increased levels of investment, increased levels of appetite in the market and increased government focus in supporting the sector,” says SRC’s Mander. However, whether government funding actually reaches farmers is something Metcalfe-Tyrrell at the University of Plymouth questions as “fundamentally it is the farmers that need to make the initial and often very expensive investment in this technology”.

As is so often the case in many industries, technology starts off at such a price point that buyers cannot afford it and must wait for the price to be lowered. Jackson at Agri-tech Cornwall believes it is not enough for robotics and automation to be a great opportunity for farmers to work in a “versatile and smart” way.

“If they do not see it as an investment, and if they do not have long enough to trial and test the equipment themselves, or have access to the data from the trials, then farmers will fail to see robotics as a worthwhile investment,” he warns.

He also warns that, when it comes to investing in new equipment, the farming industry can be all too conventional. “The majority of parties that supply to the sector are big and well known. There is a red firm of tractors, a green firm of tractors and a blue firm. And you don’t get many colours in between. They just sell a bigger tractor.”

No overnight revolution

Changing this very traditional purchasing format is going to take time and a cultural shift, as Shaw-Sutton at University of Plymouth explains: “It is not just the monetary value of this technology that farmers must agree to. Rather, they must adopt a whole different point of view. The farming community needs to view robotics as an asset for their businesses, whether that it is the kit itself or employing new staff with the expertise to use or even build such equipment.”

His colleague Metcalfe-Tyrrell concurs: “We have a job to convince farmers that this technology can genuinely benefit their business because there is not the luxury within the farming sector. There is a lot more research needed to convince farmers.”

She adds that the only way to do this is by working with them directly. Additionally, a combined approach could be key with farmers choosing to deploy robots alongside their existing, more traditional tractors, believes SRC’s Mander. “Farming equipment is expensive; people want to get the best out of the investment that they have made in their existing kit. It’s all about incremental transition rather than an overnight revolution.”

And whilst Saga Robotics’ From believes strawberry-harvesting robots could only be one or two years away from being commercially viable, Mander at SRC is more cautious with her prediction and forecasts that it will be “closer to 2030” before such technology enters the market. That being said, all parties agree that, in order to see such technology deployed in agriculture, the robots need to be seen as reliable and robust. “A robot really needs to work and operate all the time – everyday, all year round,” says From.

Appetite for change

Still, when robotic technology is eventually proven in trials across the country, no matter how lengthy, will the industry be ready to adapt to it? Mander at SRC thinks so: “We have seen tremendous appetite from farmers. To date, we have been crowdfunded. The very first community that responded, and responded very strongly, were farmers. And in terms of wider industry interest there is so much excitement in this technology.”

Whilst there may be excitement in sections of the industry Metcalfe-Tyrrell at University of Plymouth believes that convincing farmers to adapt to new technological solutions and invest robotics might not be enough to usher in the next revolution in agriculture. She stresses that more “work needs to be done within the farming community itself” to ensure the next generation are not only farmers but also technologists who can come up with the ideas for themselves.

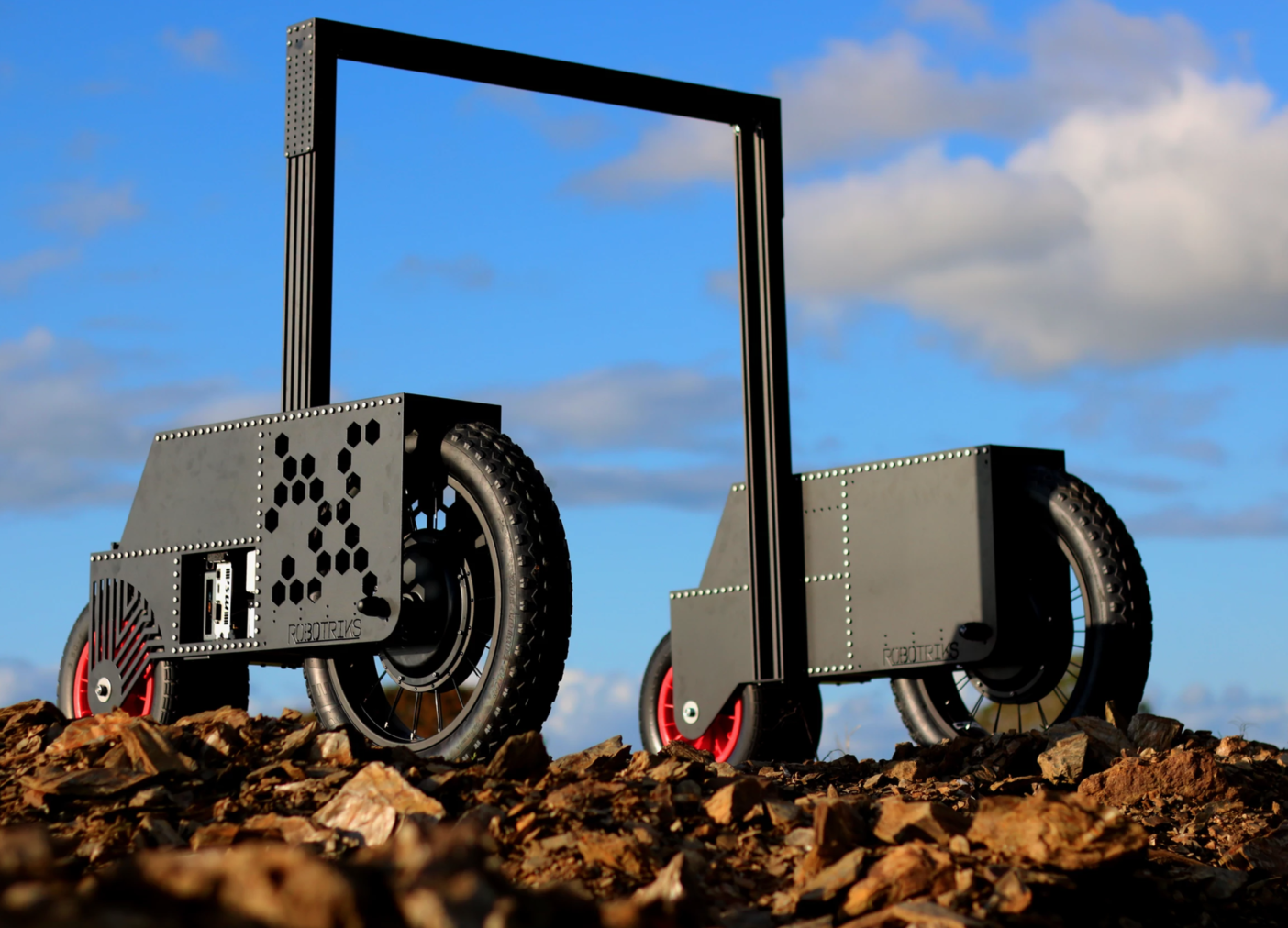

This is exactly what Shaw-Sutton did. Not only a technician at the University of Plymouth’s Faculty of Science and Engineering, he also founded Robotriks, a start-up to assist with overcoming manual labour shortages. Being from a farming background and seeing the cost of such platforms, Shaw-Sutton developed a low-cost Robotriks Traction Unit (RTU).

Designed out of need, the platform has been developed to highlight that robotic solutions do not require to be built from scratch and can instead harness mass-produced objects, such as its brushless hub motor, which is from an electric bike. Furthermore, the RTU is said to be able to fit with almost any agricultural implement and can reportedly be built within a few hours. According to Shaw-Sutton, the autonomous unit provides farmers with an introduction to building such technology.

The RTU is currently in the testing phase but Shaw-Sutton says it’s being offered commercially to researchers and the company aims for the unit to have enough functionality to offer it to a wider market over the next year.

“These things are becoming more and more accessible, you are getting more kits and more educational tools to get people into the field and the sectors,” says Sutton-Shaw. “When you start bringing in more minds, you start getting more creative and unique ideas.

“We’re now at that vantage point where everyone has the access and capability of doing that, and it is bringing that all together.”

This article originally appeared in the April 2021 issue of Robotics & Innovation Magazine