Why the fourth industrial revolution is changing the supply-chain game by consolidating other technologies in the warehouse…

According to a report by Allied Market Research, the logistics automation market is set to reach US$147.38bn (£127.52bn), growing at a CAGR of 11.9% from 2021 to 2030.

Currently, the market is segmented into organisation size, end-use industry and component and application. These segments cover industries of all kinds, from small- to medium-sized enterprises (SMEs) to fast-moving consumer goods (FMCGs) and more. And as the world’s population grows, automation in logistics will become ever more important in strengthening existing supply chains and establishing new ones.

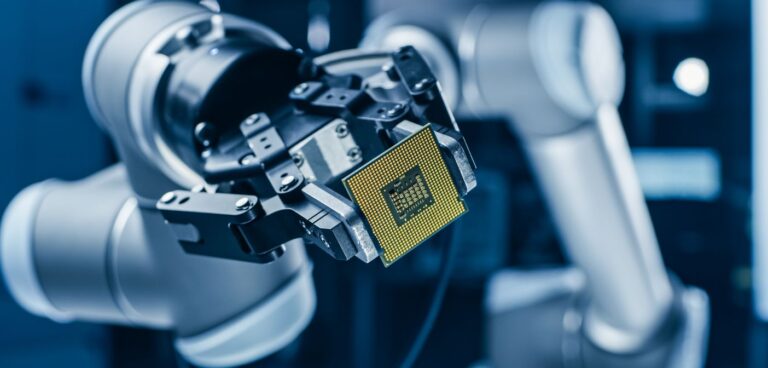

Allied Market Research states that automation has become popular among companies due to its cost-limiting nature and the increased efficiency it brings. Autonomous robotic devices such as autonomous mobile robots (AMRs), for example, can greatly improve the safety of a warehouse environment.

Kion, a German multinational manufacturer of materials handling equipment, has been addressing the issue of rising population density and the demand for e-commerce through micro-fulfilment centres. The company has also established networked and automated industrial trucks to keep up with the demand and lessen reliance on employees. By combining both automation and digital technology within the modern warehouse, the company is adapting to meet the requirements of Intralogistics 4.0.

Even flows

In practice, by adopting Industry 4.0 technology in the supply chain, logistics managers can greatly optimise their warehouse management.

This is especially important when you have a constant flow of goods incoming and outgoing. Picking and packing can also be optimised and therefore, according to supply-chain solutions provider Arvato, the digitisation of logistics involves much more than simply automating logistics processes.

Instead, it is more about optimising warehouse space, automating inventory management in both warehouses and distribution centres, which includes replenishing returns.

Logistics 4.0 and Industry 4.0 in general, when implemented correctly, can drastically improve physical processes, which, in turn, enhances employee wellbeing, can reduce environmental impact and improves safety.

However, for this to work as smoothly as possible, the existing IT processes in place, as well as any physical elements, must be as “automated as far as possible”, according to Arvato. Automated guided vehicles (AGVs), pick-to-voice, pick-to-scan, as well as AI-based technologies, can all benefit from Logistics 4.0.

Many of these processes can be simplified with the application of 4.0 and warehouses can also become paperless, thus bettering the environmental credentials of a supply chain.

Key aspects to consider

A study by Arvato, which surveyed a variety of companies from the retail, industrial and logistics sectors, found that the most important aspects of Logistics 4.0 are a fully digital process (90%), a culture of innovation (76%) and mobile access (70%), among others. By adopting Logistics 4.0, a company can greatly enhance its supply chain to create an “optimised and integrated network”, according to the research.

The article was originally published in the July 2022 issue of Robotics & Innovation